Page 20 - PIGNAT catalogue 2020 GB_092020

P. 20

CRYSTALLIZATION

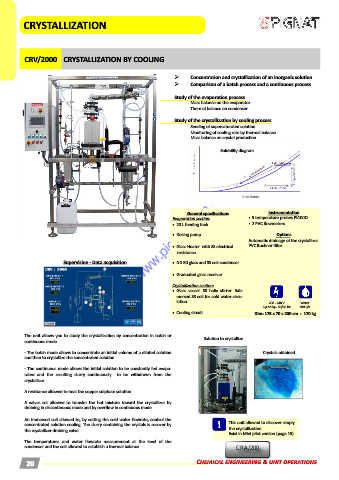

CRV/2000 CRYSTALLIZATION BY COOLING

➢ Concentration and crystallization of an inorganic solution

➢ Comparison of a batch process and a continuous process

Study of the evaporation process

Mass balance on the evaporator

Thermal balance on condenser

Study of the crystallization by cooling process

Seeding of supersaturated solution

Monitoring of cooling rate by thermal balance

Mass balance on crystal production

Solubility diagram

www.pignat.com

www.pignat.com • 5 temperature probes Pt100Ω.

General specifications

Instrumentation

Evaporation section:

• 2 PVC flowmeters.

• 20 L feeding tank.

• Dosing pump.

Options

Automatic drainage of the crystallizer

• Glass Heater with SS electrical

PVC Buchner filter.

resistance.

Supervision - Data acquisition • ND 50 glass and SS coil condenser.

• Graduated glass receiver.

Crystallization section:

• Glass vessel. SS helix stirrer. Sub-

mersed SS coil for cold water circu-

lation. 200 - 240 V Water

1ϕ or 3ϕ - 50/60 Hz 500 L/h

• Cooling circuit. Dim: 175 x 70 x 200 cm - 170 kg

The unit allows you to study the crystallization by concentration in batch or

continuous mode. Solution to crystallize

- The batch mode allows to concentrate an initial volume of a diluted solution Crystals obtained

and then to crystallize the concentrated solution.

- The continuous mode allows the initial solution to be constantly fed evapo-

rated and the resulting slurry continuously to be withdrawn from the

crystallizer.

A resistance allowed to heat the copper sulphate solution.

A valves set allowed to transfer the hot mixture toward the crystallizer by

draining in discontinuous mode and by overflow in continuous mode.

An immersed coil allowed to, by setting the cold water flowrate, control the

concentrated solution cooling. The slurry containing the crystals is recover by This unit allowed to discover simply

the crystallizer draining valve. the crystallization

Exist in Mini pilot version (page 15)

The temperatures and water flowrate measurement at the level of the

condenser and the coil allowed to establish a thermal balance.

20 Chemical engineering & unit operations