Page 21 - PIGNAT catalogue 2020 GB_092020

P. 21

CRYSTALLIZATION

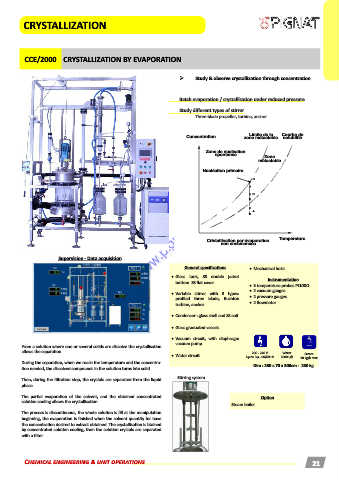

CCE/2000 CRYSTALLIZATION BY EVAPORATION

➢ Study & observe crystallization through concentration

Batch evaporation / crystallization under reduced pressure

Study different types of stirrer

Three-blade propeller, turbine, anchor

Limite de la

Concentration zone métastable Courbe de

solubilité

Zone de nucléation

spontanée Zone

métastable

Nucléation primaire

B

C A

www.pignat.com

www.pignat.com Cristallisation par évaporation Température

non ensemencée

Supervision - Data acquisition General specifications • Mechanical hoist.

• Glass tank, SS double jacket

bottom. SS flat cover. Instrumentation

• 3 temperature probes Pt100Ω.

• 2 vacuum gauges.

• Variable stirrer with 3 types:

profiled three blade, Rushton • 2 pressure gauges.

turbine, anchor. • 2 flowmeter.

• Condenser : glass shell and SS coil.

• Glass graduated vessels.

• Vacuum circuit, with diaphragm

vacuum pump.

From a solution where one or several solids are dissolve the crystallisation

allows the separation. • Water circuit 200 - 240 V Water Steam

1ϕ ou 3ϕ - 50/60 Hz 1000 L/h 10 kg/h max

During the separation, when we reach the temperature and the concentra- Dim : 250 x 70 x 300cm - 250 kg

tion needed, the dissolved compounds in the solution turns into solid.

Stirring system

Then, during the filtration step, the crystals are separated from the liquid

phase.

The partial evaporation of the solvent, and the obtained concentrated Option

solution cooling allows the crystallisation. Steam boiler.

The process is discontinuous, the whole solution is fill at the manipulation

beginning, the evaporation is finished when the solvent quantity for have

the concentration desired to extract obtained. The crystallisation is btained

by concentrated solution cooling, then the solution crystals are separated

with a filter.

Chemical engineering & unit operations 21