Page 26 - PIGNAT catalogue 2020 GB_092020

P. 26

LIQUID-LIQUID EXTRACTION

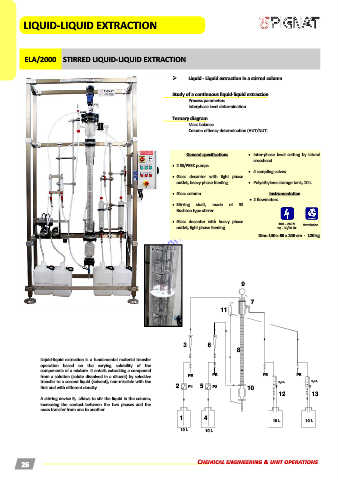

ELA/2000 STIRRED LIQUID-LIQUID EXTRACTION

➢ Liquid - Liquid extraction in a stirred column

Study of a continuous liquid-liquid extraction

Process parameters

Interphase level determination

Ternary diagram

Mass balance

Column effiency determination (HUT/NUT)

General specifications • Inter-phase level setting by lateral

crosshead.

• 2 SS/PEEK pumps.

• 4 sampling valves.

• Glass decanter with light phase

outlet, heavy phase feeding. • Polyethylene storage tank, 10 L.

• Glass column. Instrumentation

• Stirring shaft, made of SS • 2 flowmeters.

www.pignat.com

www.pignat.com Dim: 140 x 60 x 240 cm - 120 kg

Rushton type stirrer.

• Glass decanter with heavy phase

100 - 240 V

Ventilation

outlet, light phase feeding.

1ϕ - 50/60 Hz

9

7

11

3 6

8

Liquid-liquid extraction is a fundamental material transfer

operation based on the varying solubility of the

components of a mixture. It entails extracting a compound

from a solution (solute dissolved in a diluent) by selective PE PE PE PE

transfer to a second liquid (solvent), non-miscible with the 0,5 L 0,5 L

first and with different density. 2 P1 5 P2 10

12 13

A stirring device 9, allows to stir the liquid in the column,

increasing the contact between the two phases and the

mass transfer from one to another.

1 4

10 L 10 L

10 L 10 L

26 Chemical engineering & unit operations