Page 162 - Operations Strategy

P. 162

CAPACiTy CHAngE 137

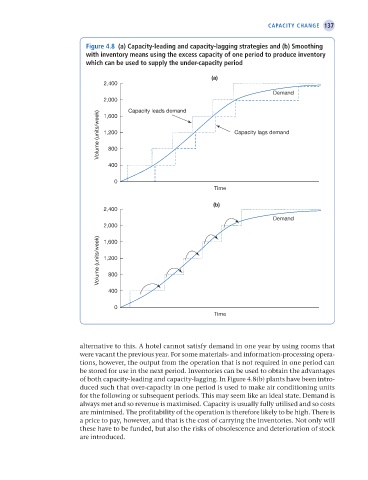

Figure 4.8 (a) Capacity-leading and capacity-lagging strategies and (b) smoothing

with inventory means using the excess capacity of one period to produce inventory

which can be used to supply the under-capacity period

(a)

2,400

Demand

2,000

Capacity leads demand

Volume (units/week) 1,200 Capacity lags demand

1,600

800

400

0

Time

(b)

2,400

Demand

2,000

Volume (units/week) 1,200

1,600

800

400

0

Time

alternative to this. A hotel cannot satisfy demand in one year by using rooms that

were vacant the previous year. For some materials- and information-processing opera-

tions, however, the output from the operation that is not required in one period can

be stored for use in the next period. Inventories can be used to obtain the advantages

of both capacity-leading and capacity-lagging. In Figure 4.8(b) plants have been intro-

duced such that over-capacity in one period is used to make air conditioning units

for the following or subsequent periods. This may seem like an ideal state. Demand is

always met and so revenue is maximised. Capacity is usually fully utilised and so costs

are minimised. The profitability of the operation is therefore likely to be high. There is

a price to pay, however, and that is the cost of carrying the inventories. Not only will

these have to be funded, but also the risks of obsolescence and deterioration of stock

are introduced.

M04 Operations Strategy 62492.indd 137 02/03/2017 13:02