Page 508 - Operations Strategy

P. 508

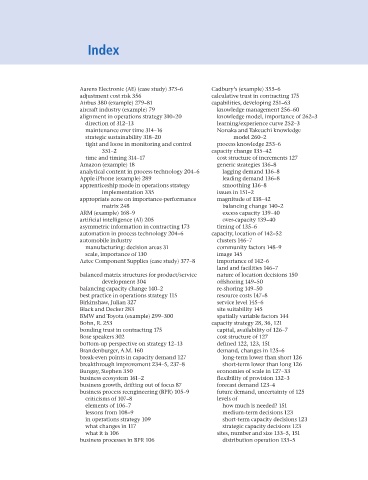

Index

Aarens Electronic (AE) (case study) 373–6 Cadbury’s (example) 355–6

adjustment cost risk 356 calculative trust in contracting 175

Airbus 380 (example) 279–81 capabilities, developing 251–63

aircraft industry (example) 79 knowledge management 256–60

alignment in operations strategy 310–20 knowledge model, importance of 262–3

direction of 312–13 learning/experience curve 252–3

maintenance over time 314–16 Nonaka and Takeuchi knowledge

strategic sustainability 318–20 model 260–2

tight and loose in monitoring and control process knowledge 253–6

351–2 capacity change 135–42

time and timing 314–17 cost structure of increments 127

Amazon (example) 18 generic strategies 136–8

analytical content in process technology 204–6 lagging demand 136–8

Apple iPhone (example) 289 leading demand 136–8

apprenticeship mode in operations strategy smoothing 136–8

implementation 335 issues in 151–2

appropriate zone on importance-performance magnitude of 138–42

matrix 248 balancing change 140–2

ARM (example) 168–9 excess capacity 139–40

artificial intelligence (AI) 205 over-capacity 139–40

asymmetric information in contracting 173 timing of 135–6

automation in process technology 204–6 capacity, location of 142–52

automobile industry clusters 146–7

manufacturing: decision areas 31 community factors 148–9

scale, importance of 130 image 145

Aztec Component Supplies (case study) 377–8 importance of 142–6

land and facilities 146–7

balanced matrix structures for product/service nature of location decisions 150

development 304 offshoring 149–50

balancing capacity change 140–2 re-shoring 149–50

best practice in operations strategy 115 resource costs 147–8

Birkinshaw, Julian 327 service level 145–6

Black and Decker 283 site suitability 145

BMW and Toyota (example) 299–300 spatially variable factors 144

Bohn, R. 253 capacity strategy 28, 36, 121

bonding trust in contracting 175 capital, availability of 126–7

Bose speakers 302 cost structure of 127

bottom-up perspective on strategy 12–13 defined 122, 123, 151

Brandenburger, A.M. 160 demand, changes in 125–6

break-even points in capacity demand 127 long-term lower than short 126

breakthrough improvement 234–5, 237–8 short-term lower than long 126

Bungay, Stephen 350 economies of scale in 127–33

business ecosystem 161–2 flexibility of provision 132–3

business growth, drifting out of focus 87 forecast demand 123–4

business process reengineering (BPR) 105–9 future demand, uncertainty of 125

criticisms of 107–8 levels of

elements of 106–7 how much is needed? 151

lessons from 108–9 medium-term decisions 123

in operations strategy 109 short-term capacity decisions 123

what changes in 117 strategic capacity decisions 123

what it is 106 sites, number and size 133–5, 151

business processes in BPR 106 distribution operation 133–5

Z20 Operations Strategy 62492.indd 483 09/03/2017 14:48