Page 348 - Programmable Logic Controllers, Fifth Edition - Mobile version

P. 348

supervised by a SCADA/HMI software package run-

Output loads

Signal sources

ning on a host computer, as illustrated in Figure 14-49.

Alarms

Temperature Process control operators monitor PLC operation on the

thermocouples

and resistance host computer and send control commands to the PLCs

temperature detectors PLC relay if required. The great advantage of a SCADA system is

Interface that data are stored automatically in a form that can be

Pressure controls

Position system Analog retrieved for later analysis without error or additional

work. Measurements are made under processor control

Force outputs

and then displayed onscreen and stored to a hard drive.

Strain PID Accurate measurements are easy to obtain, and there are

process

Speed control no mechanical limitations to measurement speed.

An important part of most SCADA implementations is

Computer alarm handling. An alarm is an announcement to the opera-

tor initiated by a process variable passing a defined limit as

Printer it approaches an undesirable or unsafe value. The announce-

ment includes audible sounds, visual indications, and mes-

sages. Properly designed alarms will notify the operator of

abnormal situations with enough time to successfully man-

Tables and

graphs age them. For this reason, alarms often have a several-second

delay associated with them to ensure the process being mon-

Hardcopy itored has stabilized before activating an alarm. Alarm man-

agement includes being able to distinguish between alarms

Spreadsheet and alerts. An alert provides a warning mechanism, but

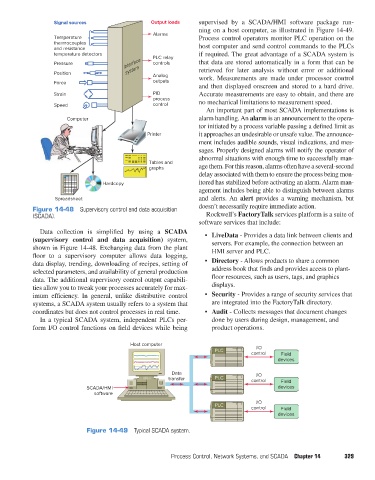

Figure 14-48 Supervisory control and data acquisition doesn’t necessarily require immediate action.

(SCADA). Rockwell’s FactoryTalk services platform is a suite of

software services that include:

Data collection is simplified by using a SCADA • LiveData - Provides a data link between clients and

(supervisory control and data acquisition) system, servers. For example, the connection between an

shown in Figure 14-48. Exchanging data from the plant HMI server and PLC.

floor to a supervisory computer allows data logging,

data display, trending, downloading of recipes, setting of • Directory - Allows products to share a common

selected parameters, and availability of general production address book that finds and provides access to plant-

data. The additional supervisory control output capabili- floor resources, such as users, tags, and graphics

ties allow you to tweak your processes accurately for max- displays.

imum efficiency. In general, unlike distributive control • Security - Provides a range of security services that

systems, a SCADA system usually refers to a system that are integrated into the FactoryTalk directory.

coordinates but does not control processes in real time. • Audit - Collects messages that document changes

In a typical SCADA system, independent PLCs per- done by users during design, management, and

form I/O control functions on field devices while being product operations.

Host computer I/O

PLC

control Field

devices

Data I/O

transfer PLC control Field

SCADA/HMI devices

software

I/O

PLC

control Field

devices

Figure 14-49 Typical SCADA system.

Process Control, Network Systems, and SCADA Chapter 14 329

pet73842_ch14_305-332.indd 329 05/11/15 4:29 PM