Page 411 - Programmable Logic Controllers, Fifth Edition - Mobile version

P. 411

Restart_Button Ladder logic

<Local:1:I.Data.1> Counter_1

RES

Enter_Limit_Sw

<Local:1:I.Data.3>

CTU

Count Up CU

L1 Inputs Counter Counter_1

Preset 50 DN

Accum 0

Restart_Button

Exit_Limit_Sw

<Local:1:I.Data.4>

CTD

Count Down CD

Counter Counter_1

Preset 50 DN

Enter_Limit_Sw 0 Output L2

Accum

Conveyor_Contactor Conveyor_Contactor C

Counter_1.DN <Local:2:O.Data.2>

Exit_Limit_Sw

FBD equivalent

CTUD_01

CTUD ... BNOT_01

Count Up/Down BNOT ...

0 0

Enter_Limit_Sw CUEnable ACC ACC Boolean Not

0 0 1

Exit_Limit_Sw CDEnable DN In Out Conveyor_Contactor

50

50 PRE

Reset

0

Restart_Button

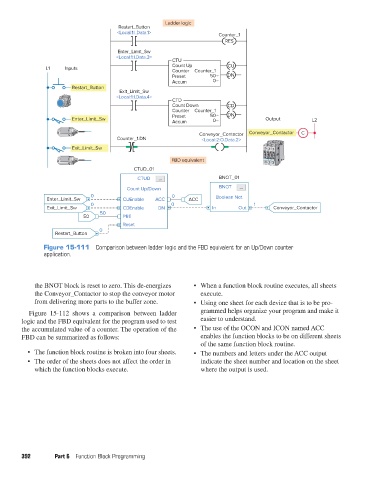

Figure 15-111 Comparison between ladder logic and the FBD equivalent for an Up/Down counter

application.

the BNOT block is reset to zero. This de-energizes • When a function block routine executes, all sheets

the Conveyor_Contactor to stop the conveyor motor execute.

from delivering more parts to the buffer zone. • Using one sheet for each device that is to be pro-

Figure 15-112 shows a comparison between ladder grammed helps organize your program and make it

logic and the FBD equivalent for the program used to test easier to understand.

the accumulated value of a counter. The operation of the • The use of the OCON and ICON named ACC

FBD can be summarized as follows: enables the function blocks to be on different sheets

of the same function block routine.

• The function block routine is broken into four sheets. • The numbers and letters under the ACC output

• The order of the sheets does not affect the order in indicate the sheet number and location on the sheet

which the function blocks execute. where the output is used.

392 Part 6 Function Block Programming

pet73842_ch15_333-394.indd 392 03/11/15 7:34 PM