Page 132 - Michigan Drill

P. 132

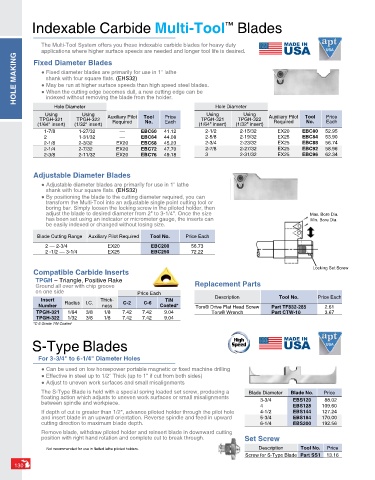

Indexable Carbide Multi-Tool Blades

™

The Multi-Tool System offers you these indexable carbide blades for heavy duty

applications where higher surface speeds are needed and longer tool life is desired.

HOLE MAKING ● Fixed diameter blades are primarily for use in 1" lathe

Fixed Diameter Blades

shank with four square flats. (EHS32)

● May be run at higher surface speeds than high speed steel blades.

● When the cutting edge becomes dull, a new cutting edge can be

indexed without removing the blade from the holder.

Hole Diameter Hole Diameter

Using Using Using Using Tool

TPGH-321 TPGH-322 Auxiliary Pilot Tool Price TPGH-321 TPGH-322 Auxiliary Pilot No. Price

(1/64" insert) (1/32" insert) Required No. Each (1/64" insert) (1/32" insert) Required Each

1-7/8 1-27/32 –– EBC60 41.12 2-1/2 2-15/32 EX20 EBC80 52.95

2 1-31/32 –– EBC64 44.08 2-5/8 2-19/32 EX25 EBC84 53.90

2-1/8 2-3/32 EX20 EBC68 45.23 2-3/4 2-23/32 EX25 EBC88 56.74

2-1/4 2-7/32 EX20 EBC72 47.70 2-7/8 2-27/32 EX25 EBC92 58.96

2-3/8 2-11/32 EX20 EBC76 49.18 3 2-31/32 EX25 EBC96 62.34

Adjustable Diameter Blades

● Adjustable diameter blades are primarily for use in 1" lathe

shank with four square flats. (EHS32)

● By positioning the blade to the cutting diameter required, you can

transform the Multi-Tool into an adjustable single point cutting tool or

boring bar. Simply loosen the locking screw in the piloted holder, then

adjust the blade to desired diameter from 2" to 3-1/4". Once the size Max. Bore Dia.

has been set using an indicator or micrometer gauge, the inserts can Min. Bore Dia.

be easily indexed or changed without losing size.

Blade Cutting Range Auxiliary Pilot Required Tool No. Price Each

2 –– 2-3/4 EX20 EBC200 56.73

2 -1/2 –– 3-1/4 EX25 EBC250 72.22

Locking Set Screw

Compatible Carbide Inserts

TPGH – Triangle, Positive Rake

Ground all over with chip groove Replacement Parts

on one side Price Each

Insert Thick- TiN Description Tool No. Price Each

Number Radius I.C. ness C-2 C-6 Coated* Torx® Drive Flat Head Screw Part TF832-285 2.61

TPGH-321 1/64 3/8 1/8 7.42 7.42 9.04 Torx® Wrench Part CTW-10 3.67

TPGH-322 1/32 3/8 1/8 7.42 7.42 9.04

*C-6 Grade TiN Coated

S-Type Blades

For 3-3/4" to 6-1/4" Diameter Holes

● Can be used on low horsepower portable magnetic or fixed machine drilling

● Effective in steel up to 1/2" Thick (up to 1" if cut from both sides)

● Adjust to uneven work surfaces and small misalignments

The S-Type Blade is held with a special spring loaded set screw, producing a Blade Diameter Blade No. Price

floating action which adjusts to uneven work surfaces or small misalignments EBS120

between spindle and workpiece. 3-3/4 88.02

4 EBS128 109.60

If depth of cut is greater than 1/2", advance piloted holder through the pilot hole 4-1/2 EBS144 127.24

and insert blade in an upward orientation. Reverse spindle and feed in upward 5-3/4 EBS184 170.00

cutting direction to maximum blade depth. 6-1/4 EBS200 192.56

Remove blade, withdraw piloted holder and reinsert blade in downward cutting

position with right hand rotation and complete cut to break through. Set Screw

Not recommended for use in flatted lathe piloted holders. Description Tool No. Price

Screw for S-Type Blade Part SS1 13.16

130