Page 28 - Buy Premium Tools ATORN Catalogue

P. 28

Drilling tools

Twist drill type N

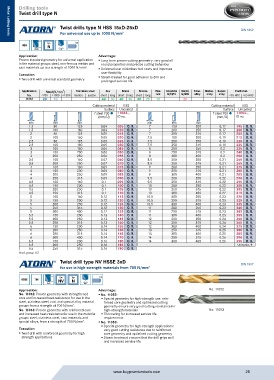

Twist drills type N HSS 15xD-25xD DIN 1869

For universal use up to 1000 N/mm 2

Metal cutting tools

Metal cutting tools

Typ HA

HSS N

20xD 118°

Application: Advantage:

Proven standard geometry for universal application Long-term proven cutting geometry: very good all-

in the material groups steel, non-ferrous metals and round properties and precise cutting behaviour

cast materials up to a strength of 1000 N/mm . 2 Universal use: minimises tool costs and improves

Execution: user flexibility

Twist drill with universal standard geometry Steam-treated for good adhesion to drill and

prolonged service life

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11063 20 10 40 50 40 30 30 20 10 20

Cutting material HSS Cutting material HSS

Surface Uncoated Surface Uncoated

f steel 700 11063... f steel 700 11063...

(mm/U) ID no. (mm/U) ID no.

mm mm mm mm mm mm

1.5 80 125 0.04 005 O. R. 7 150 200 0.17 195 O. R.

1.5 100 160 0.04 010 O. R. 7 200 250 0.17 200 O. R.

2 80 125 0.05 015 O. R. 7 250 315 0.17 205 O. R.

2 100 160 0.05 020 O. R. 7.5 150 200 0.19 215 O. R.

2.5 80 125 0.05 025 O. R. 7.5 200 250 0.19 220 O. R.

2.5 100 160 0.05 030 O. R. 7.5 250 315 0.19 225 O. R.

3 100 160 0.06 045 O. R. 8 200 250 0.2 235 O. R.

3 150 200 0.06 050 O. R. 8 250 315 0.2 240 O. R.

3 200 250 0.06 055 O. R. 8 300 400 0.2 250 O. R.

3.5 100 160 0.07 060 O. R. 8.5 200 250 0.21 260 O. R.

3.5 200 250 0.07 070 O. R. 8.5 250 315 0.21 265 O. R.

4 100 160 0.09 075 O. R. 9 200 250 0.21 275 O. R.

4 150 200 0.09 080 O. R. 9 250 315 0.21 280 O. R.

4 200 250 0.09 085 O. R. 9 300 400 0.21 285 O. R.

4 250 315 0.09 090 O. R. 9.5 200 250 0.22 290 O. R.

4.5 100 160 0.1 095 O. R. 9.5 250 315 0.22 295 O. R.

4.5 150 200 0.1 100 O. R. 10 200 250 0.22 300 O. R.

4.5 200 250 0.1 105 O. R. 10 250 315 0.22 305 O. R.

4.5 250 315 0.1 110 O. R. 10 300 400 0.22 315 O. R.

5 100 160 0.12 115 O. R. 10.5 200 250 0.23 320 O. R.

5 150 200 0.12 120 O. R. 10.5 250 315 0.23 325 O. R.

5 200 250 0.12 125 O. R. 10.5 300 400 0.23 335 O. R.

5 250 315 0.12 130 O. R. 11 200 250 0.23 340 O. R.

5 300 400 0.12 135 O. R. 11 250 315 0.23 345 O. R.

5.5 150 200 0.13 140 O. R. 11 300 400 0.23 355 O. R.

5.5 200 250 0.13 145 O. R. 12 200 250 0.24 360 O. R.

5.5 250 315 0.13 150 O. R. 12 250 315 0.24 365 O. R.

6 150 200 0.14 155 O. R. 12 300 400 0.24 375 O. R.

6 200 250 0.14 160 O. R. 13 250 315 0.25 380 O. R.

6 250 315 0.14 165 O. R. 13 300 400 0.25 385 O. R.

6 300 400 0.14 170 O. R. 14 250 315 0.26 390 O. R.

6.5 150 200 0.16 180 O. R. 14 300 400 0.26 395 O. R.

6.5 200 250 0.16 185 O. R. Unit price, €

6.5 250 315 0.16 190 O. R.

Prod. group 112

Twist drill type NV HSSE 3xD

for use in high-strength materials from 700 N/mm 2 DIN 1897

Typ Typ HA

HSSE TiN NV N

3xD 130°

Application: Advantage: No. 11052

No. 11052: Proven geometry with strengthened No. 11052:

core and increased heat-resistance for use in the Special geometry for high-strength use: rein-

steel, stainless steel, cast and special alloy material forced core geometry and optimised cutting

groups from a strength of 700 N/mm . 2 geometry ensure very good cutting resistance for

No. 11053: Proven geometry with reinforced core high-strength materials No. 11053

and increased heat-resistance for use in the material TiN coating for increased service life

groups steel, stainless steel, cast materials and requirements

special alloys, from a strength of 700 N/mm . 2 No. 11053:

Special geometry for high-strength applications:

Execution: very good cutting resistance due to reinforced

Twist drill with reinforced geometry for high- core geometry and optimised cutting geometry

strength applications Steam treatment ensures that the drill grips well

and increases service life

www.buypremiumtools.com 28