Page 17 - 5937_2019_07_Cennik_angielski_v5

P. 17

OTHER INSULATIONS

EPS SUPERPODDASZE (ATTIC) EPS

SUPERPODDASZE (ATTIC) EPS boards are applied board is placed between rafters as a self-moun-

as thermal insulation in sloping roofs. Thanks to ting (expanding) waste-free insulation element.

special longitudinal or perpendicular notches, the In addition to EPS, Termo Organika also offers other thermal insulation materials.

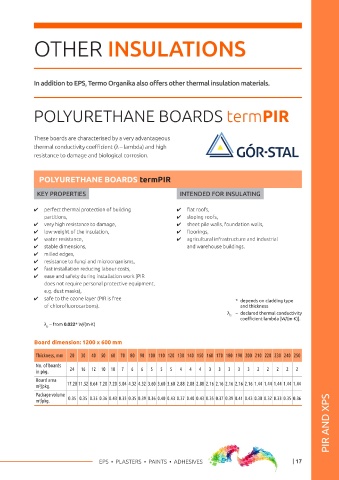

POLYURETHANE BOARDS termPIR

These boards are characterised by a very advantageous

thermal conductivity coefficient (λ – lambda) and high

Installation of insulations between the rafters with the use of SUPERPODDASZE (attic) boards – suggestions: resistance to damage and biological corrosion.

4 measure the distances between the rafters, 4 boards are placed between the rafters, slightly

4 prepare the appropriate number of boards for the compressed or bent, POLYURETHANE BOARDS termPIR

required dimension between the rafters, 4 board mounting starts with the lowermost roof

4 boards have to be 3% wider than the dimension level, KEY PROPERTIES INTENDED FOR INSULATING

between the rafters to get the effect of self- 4 board pieces which have been cut should be used

mounting (expansion) of the boards between the by placing them parallelly between the rafters in perfect thermal protection of building flat roofs,

rafters, successive layers. 4 4

partitions, 4 sloping roofs,

4 very high resistance to damage, 4 sheet pile walls, foundation walls,

4 low weight of the insulation, 4 floorings,

GROOVED EPS 4 water resistance, 4 agricultural infrastructure and industrial

4 stable dimensions, and warehouse buildings.

4 milled edges,

Grooved EPS for frame walls. It is provided with ble air circulation. This provides excellent thermal 4 resistance to fungi and microorganisms,

specially shaped surface on which grooves are insulation with simultaneous ventilation of the 4 fast installation reducing labour costs,

made in parallel to the shorter board edge to ena- space under the cover. 4 ease and safety during installation work (PIR

does not require personal protective equipment,

e.g. dust masks),

4 safe to the ozone layer (PIR is free * depends on cladding type

15 mm 50 mm 50 mm of chlorofluorocarbons). and thickness

λ – declared thermal conductivity

D

coefficient lambda [W/(m·K)].

λ – from 0.022* W/(m·K)

On special request, grooves with other dimensions can be D

made.

Board dimension: 1200 x 600 mm

Thickness, mm 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 240 250

No. of boards

in pkg. 24 16 12 10 10 7 6 6 5 5 5 4 4 4 3 3 3 3 3 2 2 2 2 2

Board area

m²/pkg. 17.28 11.52 8.64 7.20 7.20 5.04 4.32 4.32 3.60 3.60 3.60 2.88 2.88 2.88 2.16 2.16 2.16 2.16 2.16 1.44 1.44 1.44 1.44 1.44

Package volume

PIR AND XPS

m³/pkg. 0.35 0.35 0.35 0.36 0.43 0.35 0.35 0.39 0.36 0.40 0.43 0.37 0.40 0.43 0.35 0.37 0.39 0.41 0.43 0.30 0.32 0.33 0.35 0.36

EXTERNAL THERMAL INSULATION COMPOSITE SYSTEM EPS PLASTERS PAINTS ADHESIVES 17