Page 13 - PowerPoint Presentation

P. 13

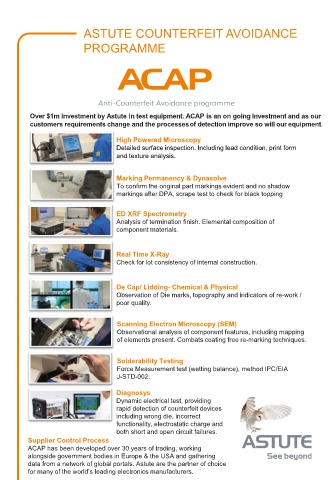

ASTUTE COUNTERFEIT AVOIDANCE

PROGRAMME

Over $1m investment by Astute in test equipment. ACAP is an on going investment and as our

customers requirements change and the processesof detection improve so will our equipment.

High Powered Microscopy

Detailed surface inspection. Including lead condition, print form

and texture analysis.

Marking Permanency & Dynasolve

To confirm the original part markings evident and no shadow

markings after DPA, scrape test to check for black topping

ED XRF Spectrometry

Analysis of termination finish. Elemental composition of

component materials.

Real Time X-Ray

Check for lot consistency of internal construction.

De Cap/ Lidding- Chemical & Physical

Observation of Die marks, topography and indicators of re-work /

poor quality.

Scanning Electron Microscopy (SEM)

Observational analysis of component features, including mapping

of elements present. Combats coating free re-marking techniques.

Solderability Testing

Force Measurement test (wetting balance), method IPC/EIA

J-STD-002.

Diagnosys

Dynamic electrical test, providing

rapid detection of counterfeit devices

including wrong die, incorrect

functionality, electrostatic charge and

both short and open circuit failures.

Supplier Control Process

ACAP has been developed over 30 years of trading, working

alongside government bodies in Europe & the USA and gathering

data from a network of global portals. Astute are the partner of choice

for many of the world’s leading electronics manufacturers.