Page 102 - SAPEM-Chapter-10-2nd-edition-2014

P. 102

South African Pavement Engineering Manual

Chapter 10: Pavement Design

The stress-sensitivity causes the stiffness of the material to decrease when the material is placed over a weaker

support. This decrease in stiffness occurs where the support layer is soft, causing a tendency for the overlying layers

to bend into the support, thereby increasing the likelihood of higher shear and tensile forces in the overlying layers.

This effect limits the stiffness obtained in the layer. By placing a limit on the modular ratio that can be sustained for

a specific material, it is ensured that the stiffness value assumed for that layer is realistic, given the material quality

and stiffness of the support. In essence, the concept of a limiting modular ratio for materials ensures that stress-

sensitive stiffness behaviour is implicitly taken into account.

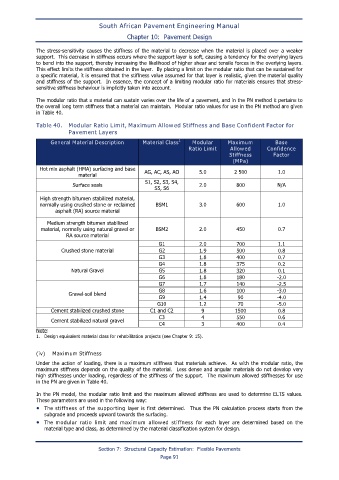

The modular ratio that a material can sustain varies over the life of a pavement, and in the PN method it pertains to

the overall long term stiffness that a material can maintain. Modular ratio values for use in the PN method are given

in Table 40.

Table 40. Modular Ratio Limit, Maximum Allowed Stiffness and Base Confident Factor for

Pavement Layers

General Material Description Material Class Modular Maximum Base

1

Ratio Limit Allowed Confidence

Stiffness Factor

(MPa)

Hot mix asphalt (HMA) surfacing and base

material AG, AC, AS, AO 5.0 2 500 1.0

S1, S2, S3, S4,

Surface seals 2.0 800 N/A

S5, S6

High strength bitumen stabilized material,

normally using crushed stone or reclaimed BSM1 3.0 600 1.0

asphalt (RA) source material

Medium strength bitumen stabilized

material, normally using natural gravel or BSM2 2.0 450 0.7

RA source material

G1 2.0 700 1.1

Crushed stone material G2 1.9 500 0.8

G3 1.8 400 0.7

G4 1.8 375 0.2

Natural Gravel G5 1.8 320 0.1

G6 1.8 180 -2.0

G7 1.7 140 -2.5

G8 1.6 100 -3.0

Gravel-soil blend

G9 1.4 90 -4.0

G10 1.2 70 -5.0

Cement stabilized crushed stone C1 and C2 9 1500 0.8

C3 4 550 0.6

Cement stabilized natural gravel

C4 3 400 0.4

Note:

1. Design equivalent material class for rehabilitation projects (see Chapter 9: 15).

(iv) Maximum Stiffness

Under the action of loading, there is a maximum stiffness that materials achieve. As with the modular ratio, the

maximum stiffness depends on the quality of the material. Less dense and angular materials do not develop very

high stiffnesses under loading, regardless of the stiffness of the support. The maximum allowed stiffnesses for use

in the PN are given in Table 40.

In the PN model, the modular ratio limit and the maximum allowed stiffness are used to determine ELTS values.

These parameters are used in the following way:

• The stiffness of the supporting layer is first determined. Thus the PN calculation process starts from the

subgrade and proceeds upward towards the surfacing.

• The modular ratio limit and maximum allowed stiffness for each layer are determined based on the

material type and class, as determined by the material classification system for design.

Section 7: Structural Capacity Estimation: Flexible Pavements

Page 91