Page 52 - UL_Report On_Part 1

P. 52

43 IITGN-UL/Façade 44 IITGN-UL/Façade

(d) Role of POP and cement boards in providing fire protection to Cement boards did not allow structural temperature to rise near

deck slab beam and slab sections thus protecting from direct fire exposure.

After 6 min from ignition, maximum temperature at roof level was

685°C whereas near steel beam beneath cement board it was 25°C.

• Material properties of POP and cement board Major failure of cement boards at ground level was observed around

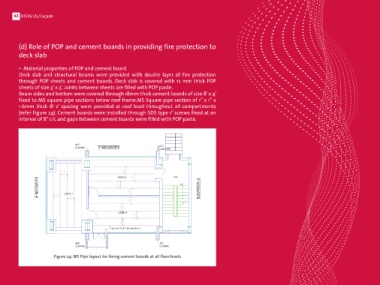

Deck slab and structural beams were provided with double layer of fire protection 10.5 minutes during flashover when temperatures reached around

through POP sheets and cement boards. Deck slab is covered with 12 mm thick POP 800°C.

sheets of size 3’ x 3’. Joints between sheets are filled with POP paste. Cement boards at first floor level failed locally at around 12 minutes

Beam sides and bottom were covered through 18mm thick cement boards of size 8’ x 4’ and major failure was observed around 17 minutes thus exposing

fixed to MS square pipe sections below roof frame.MS Square pipe section of 1” x 1” x members to direct heat. Cement boards at second floor level were

1.6mm thick @ 2’ spacing were provided at roof level throughout all compartments intact as fire failed to propagate at higher level from first floor.

(refer Figure 24). Cement boards were installed through SDS type 1” screws fixed at an Closed spacing of screws during installation helped cement boards to

interval of 8” c/c and gaps between cement boards were filled with POP paste.

avoid premature failures. Workmanship during structural fire

protection is important. Thickness of cement boards also plays an

important role in providing resistance to exposed fire. Image 9: Local failure of cement boards at ground floor level

ACP ACP

CLADING ELEVATION-3 CLADDING

+ + + + + + + +

+ + + + + + + +

+ + + +

+ + + + + + + + + + + +

+ + + + + POP sheet

+ + +

+ + +

+ + + + +

+ + + + + + +

+

+ + + + +

+ + +

610 610

CABIN-2 610 2320 Cement board

610 UP ELEVATION-2 8’’ spacing

610

610 CABIN-1

610

ELEVATION-4

610

610

CABIN-3

610

+ + + + MS square pipe

+ + + + 610 SDS Screw

+ + + + + + + +

+

+

+

ms pipe 1 x 1 x 1.6 mm thick + + + + + + + + + + + + + 1’’ x 1’’ x 1.6mm

+ + + + +

+ + + + + + + ++ + +

+ + + + + +

+ + + + +

+ + + + +

ACP ACP

CLADING CLADING

Figure 24: MS Pipe layout for fixing cement boards at all floor levels

Image 10: Local failure of cement boards at first floor level