Page 54 - BlueFastening-Systems_Brochure_07192017

P. 54

TAPTITE 2000® – Thread-rolling in metals

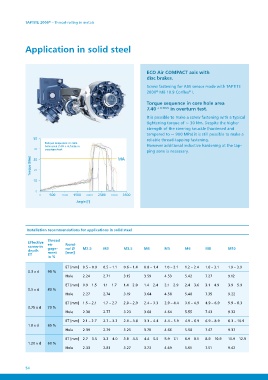

Application in solid steel

Torque sequence in core ECO Air COMPACT axis with

hole area 7.40 + 0.1mm in disc brakes.

overturn test

Screw fastening for ABS sensor made with TAPTITE

2000® M8 10.9 Corflex® I.

Torque sequence in core hole area

7.40 + 0.1mm in overturn test.

It is possible to make a screw fastening with a typical

tightening torque of ~ 30 Nm. Despite the higher

strength of the steering knuckle (hardened and

tempered to ~ 900 MPa) it is still possible to make a

reliable thread-tapping fastening.

However additional inductive hardening at the tap-

ping zone is necessary.

Torque [Nm]

Angle [°]

Installation recommendations for applications in solid steel

Effective Thread Nomi- M2.5 M3 M3.5 M4 M5 M6 M8 M10

screw-in en- nal Ø

depth gage- [mm]

ET ment

in %

ET [mm] 0.5 – 0.9 0.5 – 1.1 0.6 – 1.4 0.8 – 1.4 1.0 – 2.1 1.2 – 2.4 1.6 – 3.1 1.9 – 3.9

2.71 3.15 3.59 4.53 5.42 7.27 9.12

0.3 x d 90 % 1.1 – 1.7 1.4 – 2.0 1.4 – 2.4 2.1 – 2.9 2.4 – 3.6 3.1 – 4.9 3.9 – 5.9

2.74 3.19 3.64 4.58 5.48 7.35 9.22

Hole 2.24 1.7 – 2.7 2.0 – 2.9 2.4 – 3.3 2.9 – 4.4 3.6 – 4.9 4.9 – 6.9 5.9 – 8.3

2.77 3.23 3.68 4.64 5.55 7.43 9.32

ET [mm] 0.9 – 1.5 2.7 – 3.3 2.9 – 3.8 3.3 – 4.4 4.4 – 5.9 4.9 – 6.9 6.9 – 8.9 8.3 – 10.9

2.79 3.25 3.70 4.66 5.58 7.47 9.37

0.5 x d 80 % 3.3 – 4.0 3.8 – 4.5 4.4 – 5.5 5.9 – 7.1 6.9 – 8.1 8.9 – 10.9 10.9 – 12.9

2.81 3.27 3.73 4.69 5.61 7.51 9.42

Hole 2.27

ET [mm] 1.5 – 2.1

0.75 x d 70 %

Hole 2.30

ET [mm] 2.1 – 2.7

1.0 x d 65 %

Hole 2.39

ET [mm] 2.7 – 3.5

1.20 x d 60 %

Hole 2.33

12 54