Page 50 - BlueFastening-Systems_Brochure_07192017

P. 50

TAPTITE 2000® – Thread-rolling in metals

Application in cast aluminium

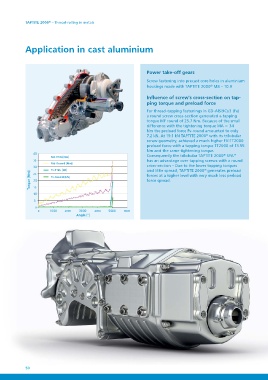

Torque [Nm] Md-TT2k[Nm] Power take-off gears

Md-Round [Nm]

Fv-TT2k [kN] Screw fastening into precast core holes in aluminium

Fv-Round [kN] housings made with TAPTITE 2000® M8 – 10.9

Influence of screw's cross-section on tap-

ping torque and preload force

For thread-tapping fastenings in GD-AlSi9Cu3 (Fe)

a round screw cross-section generated a tapping

torque MF round of 25.7 Nm. Because of the small

difference with the tightening torque MA = 34

Nm the preload force Fv-round amounted to only

7.2 kN. At 19.1 kN TAPTITE 2000® with its trilobular

screw geometry, achieved a much higher FV-TT2000

preload force with a tapping torque TT2000 of 13.55

Nm and the same tightening torque.

Consequently the trilobular TAPTITE 2000® SPA™

has an advantage over tapping screws with a round

cross-section – Due to the lower tapping torques

and little spread, TAPTITE 2000® generates preload

forces at a higher level with very much less preload

force spread.

Angle [°]

08 50