Page 21 - ST Sept

P. 21

WELDING WELDING

Eddy current weld crack detection 10 ... 15 % compared to the electrical conductivity and a length of more than 1 mm, located

of the base metal. The electrical conductivity of B95 at a depth of 1 mm.

alloys, AMg6 alloys and others can decrease by 15 Eddy current weld crack detection

The physical foundations of the eddy current ... 30 %. In the presence of defects such as sticking can be used to measure the thickness

weld crack detection method can be explained as or lack of penetration, the electrical conductivity of of galvanic, paint and varnish and heat-

follows. If two inductors L1 and L2 are installed side the cast core and the base metal are approximately insulating coatings, pipe walls, hollow

by side (for example, transformers without cores) the same. parts and thin-sheet structures with

and a current is passed through the L1 coil (Fig. 1), then when the current strength in it or the The method of eddy-current weld crack one-sided access to them, as well as the

relative position of the coils changes, an electromotive force will be induced in the L2 coil. detection has not yet found wide application in the diameters of rods and wires. However,

In eddy current weld crack detection, the function of one of the inductors is performed by inspection of welded seams, since the electrical in a number of cases, the practical

a metal plate 1, in which eddy currents 2 are induced (Fig. 2), flowing in the surface layer of the conductivity of individual zones of the seam and application of this method is hampered

metal from the side of the coil. The density and distribution of eddy currents in a metal depend the heat-affected zone changes significantly, which by the inhomogeneity of the properties

on its geometric and electrophysical parameters. creates strong interference when detecting welding of the joint materials and the deviation

If in the diagram shown in Fig. 2, the metal plate will be replaced with a welded joint defects. of the dimensions of the parts from the

containing defects, then the resistance of the surface layer will increase, which will lead to a specified ones, even within tolerances.

weakening of eddy currents, which is recorded by the sensor coil. Classification of energy field

systems. Energy field systems, or eddy

current converters (ECC), are subdivided

into external checkpoint - in which the

coil with current covers the controlled

welded joint (Fig. 4, a), internal bushing

- in which the coil is inserted into the

joint (Fig. 4, b), and consignment notes

- in which the coil is installed on the butt

joint (Fig. 4, c). In the ECC of the first

two types, the electromagnetic wave

from the landing system propagates in

the direction of the controlled connection,

and in the ECC of the third type, along its

surface.

Measuring coils (sensors) are

made separately from the energy field

(generator) ones and are placed near

the surface of the welded joint. External

checkpoints ECC are used to control

linear objects and small parts. With the

help of internal bushing ECCs, the inner

surface of pipes and holes in various

parts is controlled. Overhead ECCs are

used mainly for quality control of objects

with flat surfaces and objects of complex

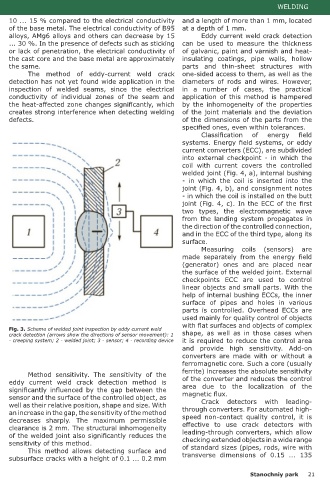

Fig. 3. Scheme of welded joint inspection by eddy current weld

crack detection (arrows show the directions of sensor movement): 1 shape, as well as in those cases when

- creeping system; 2 - welded joint; 3 - sensor; 4 - recording device it is required to reduce the control area

Fig. 1. A diagram of two interconnected Fig. 2. Diagram of the formation of eddy currents in a metal plate: 1 and provide high sensitivity. Add-on

inductors L1 and L2: Ф - magnetic flux - metal plate; 2 - eddy currents; L - inductor; Ф - magnetic flux converters are made with or without a

ferromagnetic core. Such a core (usually

ferrite) increases the absolute sensitivity

Method sensitivity. The sensitivity of the

Control technique. The inspection process by eddy current weld crack detection (Fig. 3) eddy current weld crack detection method is of the converter and reduces the control

includes the following basic operations: significantly influenced by the gap between the area due to the localization of the

• external examination of the welded joint and elimination of external defects that impede sensor and the surface of the controlled object, as magnetic flux.

the inspection; well as their relative position, shape and size. With Crack detectors with leading-

• installation of the climbing system 1 on the controlled welded joint 2 and passing the an increase in the gap, the sensitivity of the method through converters. For automated high-

current through the excitation coil; decreases sharply. The maximum permissible speed non-contact quality control, it is

• scanning the surface of the welded joint with sensor 3 and registering the signal with clearance is 2 mm. The structural inhomogeneity effective to use crack detectors with

device 4; of the welded joint also significantly reduces the leading-through converters, which allow

• decoding of control results and evaluation of connection quality. sensitivity of this method. checking extended objects in a wide range

Eddy current testing is used to inspect spot welding of aluminum alloys. In the presence This method allows detecting surface and of standard sizes (pipes, rods, wire with

of a cast core, the electrical conductivity of D16 alloys and Amg alloys in its zone decreases by subsurface cracks with a height of 0.1 ... 0.2 mm transverse dimensions of 0.15 ... 135

20 Stanochniy park Stanochniy park 21