Page 16 - ST Sept

P. 16

METALWORKING EQUIPMENT METALWORKING EQUIPMENT

AND TOOLS AND TOOLS

● running-in wear h0, µm, as the amount under the following conditions: sliding hardening has the minimum values of the friction coefficient, running-in time and wear. The

of approach, determined at the time of the end speed υ = 1 m / s; normal loading force N = wear curves for samples of P18 steel and with a coating of the Ti-Al-N and Mo-Cr-N systems are

of running-in t0; 100 ± 0.5 %, N (corresponds to pressures characterized by an accelerated increase in wear after wear of the coating. The wear curve for

● value of the coefficient of friction at the calculated according to Hertz, about 150 45 steel after CEMT is more stable.

end of tests f MPa); the type of initial contact is plastic According to the results of tribotechnical tests, it was found that the rate of wear of the

● f0 / f is the ratio of the maximum value saturated; type of lubrication - boundary; friction surface of samples of normalized 45 steel with a gradient structure of the surface layer

of the friction coefficient during the running-in type of lubrication - by dipping; the leading after implantation with tungsten carbides and subsequent electromechanical hardening during

period f0 to its value at the end of the tests f; type of wear is fatigue; lubricant - industrial the period of normal wear is less comparing (values for the total test time are indicated in

● average value of the wear rate during oil I - 20A (GOST 20799 - 88); indenter parentheses):

the period of normal wear material - hard alloy VK8; total test time of ● with heat-treated samples - 2.4 (2.7) times;

Ih = (h - h0) / (L - L0), each sample - 8 hours. ● with samples after PVD (coating of the Ti-Al-N system) - 2.2 (1.7) times;

where h, μm is the total amount of sample wear The results of testing samples ● with samples after PVD (coating system Mo-Cr-N) - 2.1 (1.6) times.

during the test; L, μm - the friction path traversed processed using the above technologies The wear resistance of R18 steel with various coatings according to the test results (Table 6)

by the sample surface during the test; L0 = 3.6• on the modernized MI-1M installation are belongs to the 7th class, and the wear resistance of 45 steel with a gradient structure to the

109 • t0 • υ, μm - friction path traversed by the presented in Table 6. 8th class.

sample surface during the running-in time; In Table 6, in addition to the value Thus, the high wear resistance of the gradient structure of the 45 steel layer with implanted

● the value of the wear rate for the total of wear h, indicators of the intensity of tungsten carbides is a consequence of compositional hardening due to the formation of highly

test time IhΣ = h / L. wear are presented. Wear resistance is the dispersed carbide structures (Fig. 2) based on tungsten carbides (size less than 1 μm) of

The choice of the optimal method of reciprocal of the wear rate. various morphologies (mesh, thread, grain), and as a consequence, higher values of hardness

hardening the friction surfaces according to Fig. 3 - 6 show the test results of in comparison with the hardness of a typical tool R18 steel (Table 4, Table 5).

the parameters of tribotechnical tests can be samples with graphs of changes in wear and

made on the basis of the definition of the above coefficient of friction over time. Comparison

criteria and their comparison. In this case, the of the results of tribotechnical tests of the

more wear-resistant is the friction surface with samples by the normalized method showed Table 6.

lower values of the wear intensity, duration that 45 steel with a gradient structure of Results of tribotechnical tests on the upgraded MI-1M installation

running-in, coefficient of friction, as well as with the surface layer with implanted tungsten

a falling characteristic of the curve of changing carbides and subsequent electromechanical tribotechnical indicator Indicator value for the sample

the coefficient of friction over time. quality Р18 steel Р18 steel + Р18 steel + 45 steel +

Tests of the samples were carried out Ti-Al-N Mo-Cr-N CEMT

conformability t0, h 1,12 0,58 0,75 0,45

h0, μm 7,5 1,30 1,50 1,70

f0/f 1,61 1,42 1,46 1,19

antifrictionality f 0,31 0,32 0,25 0,24

wear resistance h, μm 16,1 9,70 9,60 4,6

lh·10 -10 3,44 3,12 3,09 1,44

lhƩ·10 -10 5,55 3,35 3,32 2,03

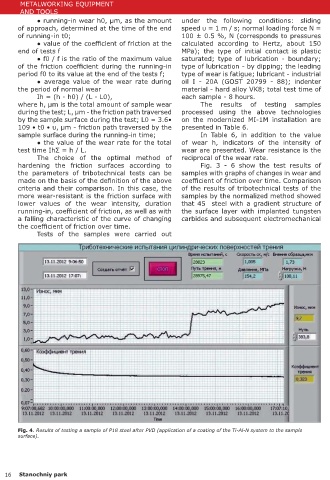

Fig. 5. Results of testing a sample of P18 steel after

Fig. 4. Results of testing a sample of P18 steel after PVD (application of a coating of the Ti-Al-N system to the sample PVD (application of a coating of the Mo-Cr-N system

surface). to the sample surface

16 Stanochniy park Stanochniy park 17