Page 54 - TECHNICAL SPECIFICATION FOR PALM OIL REFINING_rev.1 - Copy_Float

P. 54

OFFER NO. KMIPL/P16E0097R7

100 TPD PHYSICAL REFINERY AND FRACTIONATION

Page No. 54/69

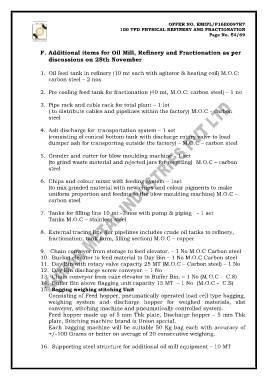

F. Additional items for Oil Mill, Refinery and Fractionation as per

discussions on 25th November

1. Oil feed tank in refinery (10 mt each with agitator & heating coil) M.O.C:

carbon steel – 2 nos

2. Pre cooling feed tank for fractionation (40 mt, M.O.C: carbon steel) – 1 no

3. Pipe rack and cable rack for total plant – 1 lot

( to distribute cables and pipelines within the factory) M.O.C – carbon

steel

4. Ash discharge for transportation system – 1 set

(consisting of conical bottom tank with discharge rotary valve to load

dumper ash for transporting outside the factory) – M.O.C – carbon steel

5. Grinder and cutter for blow moulding machine – 1 set

(to grind waste material and rejected jars for recycling) M.O.C – carbon

steel

6. Chips and colour mixer with feeding system – 1set

(to mix grinded material with new chips and colour pigments to make

uniform proportion and feeding to the blow moulding machine) M.O.C –

carbon steel

7. Tanks for filling line 10 mt -2 nos with pump & piping - 1 set

Tanks M.O.C – stainless steel

8. External tracing line (for pipelines includes crude oil tanks to refinery,

fractionation, tank farm, filling section) M.O.C – copper

9. Chain conveyor from storage to feed elevator. – 1 No M.O.C Carbon steel

10. Bucket elevator to feed material to Day Bin – 1 No M.O.C Carbon steel

11. Day Bin with rotary valve capacity 25 MT (M.O.C – Carbon steel) – 1 No

12. Day Bin discharge screw conveyor. – 1 No

13. Chain conveyor from cake elevator to Buffer Bin. – 1 No (M.O.C - C.S)

14. Buffer Bin above Bagging unit capacity 15 MT – 1 No (M.O.C - C.S)

15. Bagging weighing stitching Unit

Consisting of Feed hopper, pneumatically operated load cell type bagging,

weighing system and discharge hopper for weighed materials, slat

conveyor, stitching machine and pneumatically controlled system.

Feed hopper made up of 5 mm Thk plate, Discharge hopper – 5 mm Thk

plate, Stitching machine brand is Union special.

Each bagging machine will be suitable 50 Kg bag each with accuracy of

+/-100 Grams or better on average of 20 consecutive weighing.

16. Supporting steel structure for additional oil mill equipment – 10 MT