Page 78 - Soudage

P. 78

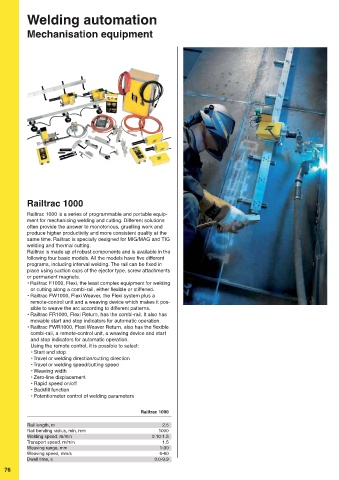

Welding automation

Mechanisation equipment

Railtrac 1000

Railtrac 1000 is a series of programmable and portable equip-

ment for mechanising welding and cutting. Different solutions

often provide the answer to monotonous, gruelling work and

produce higher productivity and more consistent quality at the

same time. Railtrac is specially designed for MIG/MAG and TIG

welding and thermal cutting.

Railtrac is made up of robust components and is available in the

following four basic models. All the models have five different

programs, including interval welding. The rail can be fixed in

place using suction cups of the ejector type, screw attachments

or permanent magnets.

• Railtrac F1000, Flexi, the least complex equipment for welding

or cutting along a combi-rail, either flexible or stiffened.

• Railtrac FW1000, Flexi Weaver, the Flexi system plus a

remote-control unit and a weaving device which makes it pos-

sible to weave the arc according to different patterns.

• Railtrac FR1000, Flexi Return, has the combi-rail. It also has

movable start and stop indicators for automatic operation.

• Railtrac FWR1000, Flexi Weaver Return, also has the flexible

combi-rail, a remote-control unit, a weaving device and start

and stop indicators for automatic operation.

Using the remote control, it is possible to select:

• Start and stop

• Travel or welding direction/cutting direction

• Travel or welding speed/cutting speed

• Weaving width

• Zero-line displacement

• Rapid speed on/off

• Backfill function

• Potentiometer control of welding parameters

Railtrac 1000

Rail length, m 2.5

Rail bending radius, min, mm 1000

Welding speed, m/min 0.10-1.5

Transport speed, m/min 1.5

Weaving range, mm 1-30

Weaving speed, mm/s 6-60

Dwell time, s 0.0-9.9

76