Page 19 - Laboratory manual for students FAR222 2019 20

P. 19

FAR 222 Dosage Form II Laboratory Manual

ii. Dry heat sterilisation

Sterilisation by dry heat is usually carried out in a hot air oven. This method of heating is

utilised to sterilise products such as oils, powders and certain impregnated dressing. Cycles

recommended in the BP 1988 are shown in Table 7.

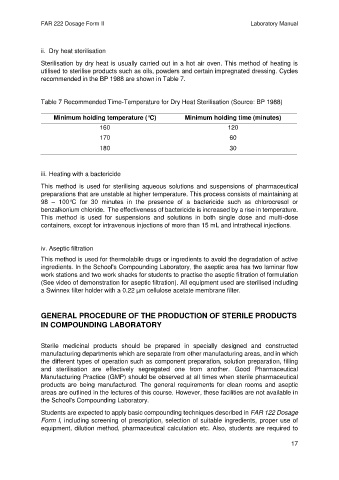

Table 7 Recommended Time-Temperature for Dry Heat Sterilisation (Source: BP 1988)

Minimum holding temperature (°C) Minimum holding time (minutes)

160 120

170 60

180 30

iii. Heating with a bactericide

This method is used for sterilising aqueous solutions and suspensions of pharmaceutical

preparations that are unstable at higher temperature. This process consists of maintaining at

98 – 100°C for 30 minutes in the presence of a bactericide such as chlorocresol or

benzalkonium chloride. The effectiveness of bactericide is increased by a rise in temperature.

This method is used for suspensions and solutions in both single dose and multi-dose

containers, except for intravenous injections of more than 15 mL and intrathecal injections.

iv. Aseptic filtration

This method is used for thermolabile drugs or ingredients to avoid the degradation of active

ingredients. In the School's Compounding Laboratory, the aseptic area has two laminar flow

work stations and two work shacks for students to practise the aseptic filtration of formulation

(See video of demonstration for aseptic filtration). All equipment used are sterilised including

a Swinnex filter holder with a 0.22 µm cellulose acetate membrane filter.

GENERAL PROCEDURE OF THE PRODUCTION OF STERILE PRODUCTS

IN COMPOUNDING LABORATORY

Sterile medicinal products should be prepared in specially designed and constructed

manufacturing departments which are separate from other manufacturing areas, and in which

the different types of operation such as component preparation, solution preparation, filling

and sterilisation are effectively segregated one from another. Good Pharmaceutical

Manufacturing Practice (GMP) should be observed at all times when sterile pharmaceutical

products are being manufactured. The general requirements for clean rooms and aseptic

areas are outlined in the lectures of this course. However, these facilities are not available in

the School's Compounding Laboratory.

Students are expected to apply basic compounding techniques described in FAR 122 Dosage

Form I, including screening of prescription, selection of suitable ingredients, proper use of

equipment, dilution method, pharmaceutical calculation etc. Also, students are required to

17