Page 30 - demo

P. 30

PROCESS & TECHNOLOGY FOR METHANOL AND DME

The major gasifier configurations are:

• Moving Bed and Fixed Bed

• Fluidized Bed

• Entrained Bed

• Transport Bed

The names themselves imply the modes of operation. For the moving bed, there could be

co-current or counter-current flow of gas and carbon source. The main characteristics for the

different configurations are summarized in table:

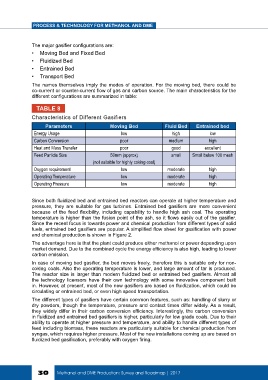

TABLE 8

Characteristics of Different Gasifiers

Parameters Moving Bed Fluid Bed Entrained bed

Energy Usage low high low

Carbon Conversion poor medium high

Heat and Mass Transfer poor good excellent

Feed Particle Size 50mm (approx) small Small below 100 mesh

(not suitable for highly coking coal)

Oxygen requirement low moderate high

Operating Temperature low moderate high

Operating Pressure low moderate high

Since both fluidized bed and entrained bed reactors can operate at higher temperature and

pressure, they are suitable for gas turbines. Entrained bed gasifiers are more convenient

because of the feed flexibility, including capability to handle high ash coal. The operating

temperature is higher than the fusion point of the ash, so it flows easily out of the gasifier.

Since the recent focus is towards power and chemical production from different types of solid

fuels, entrained bed gasifiers are popular. A simplified flow sheet for gasification with power

and chemical production is shown in Figure 2.

The advantage here is that the plant could produce either methanol or power depending upon

market demand. Due to the combined cycle the energy efficiency is also high, leading to lower

carbon emission.

In case of moving bed gasifier, the bed moves freely, therefore this is suitable only for non-

coking coals. Also the operating temperature is lower, and large amount of tar is produced.

The reactor size is larger than modern fluidized bed or entrained bed gasifiers. Almost all

the technology licensors have their own technology with some innovative component built

in. However, at present, most of the new gasifiers are based on fluidization, which could be

circulating or entrained bed, or even high speed transportation.

The different types of gasifiers have certain common features, such as: handling of slurry or

dry powders, though the temperature, pressure and contact times differ widely. As a result,

they widely differ in their carbon conversion efficiency. Interestingly, the carbon conversion

in fluidized and entrained bed gasifiers is higher, particularly for low grade coals. Due to their

ability to operate at higher pressure and temperature, and ability to handle different types of

feed including biomass, these reactors are particularly suitable for chemical production from

syngas, which requires higher pressure. Most of the new installations coming up are based on

fluidized bed gasification, preferably with oxygen firing.

30 Methanol and DME Production: Survey and Roadmap | 2017