Page 33 - demo

P. 33

PROCESS & TECHNOLOGY FOR METHANOL AND DME

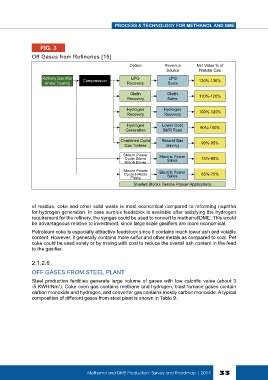

FIG. 3

Off Gases from Refineries [15]

Option Revenue Net Value % of

Source Natural Gas

Refinery Gas After Compression LPG LPG 120%-130%

Amine Treating Recovery Sales

Olefin Olefin 110%-120%

Recovery Sales

Hydrogen Hydrogen

Recovery Recovery 100%-120%

Hydrogen Lower Cost

Generation SMR Feed 90%-100%

Combined Cycle Natural Gas 90%-95%

Gas Turbine Saving

Steam Power Electric Power

Cycle Stand Sales 75%-80%

Alone Boiler

Steam Power Electric Power

Cycle HRSG Sales 65%-75%

Firing

Shaded Blocks Denote Praxair Applications

of residue, coke and other solid waste is most economical compared to reforming naphtha

for hydrogen generation. In case surplus feedstock is available after satisfying the hydrogen

requirement for the refinery, the syngas could be used to convert to methanol/DME. This would

be advantageous relative to investment, since large scale gasifiers are more economical.

Petroleum coke is especially attractive feedstock since it contains much lower ash and volatile

content. However, it generally contains more sulfur and other metals as compared to coal. Pet

coke could be used solely or by mixing with coal to reduce the overall ash content in the feed

to the gasifier.

2.1.2.6

OFF GASES FROM STEEL PLANT

Steel production facilities generate large volume of gases with low calorific value (about 3

-5 KWH/Nm ). Coke oven gas contains methane and hydrogen, blast furnace gases contain

3

carbon monoxide and hydrogen, and converter gas contains mostly carbon monoxide. A typical

composition of different gases from steel plant is shown in Table 9.

Methanol and DME Production: Survey and Roadmap | 2017 33