Page 31 - demo

P. 31

PROCESS & TECHNOLOGY FOR METHANOL AND DME

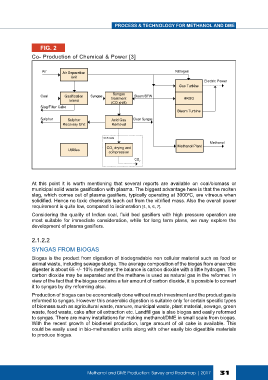

FIG. 2

Co- Production of Chemical & Power [3]

Air Air Separation Nitrogen

Unit

Electric Power

Gas Turbine

Syngas

Coal Gasification Syngas Steam/BFW

Island treatment HRSG

(CO shift)

Slag/Filter Cake

Steam Turbine

Sulphur Sulphur Acid Gas Clean Syngas

Recovery Unit Removal

CCS code

Methanol

CO drying and Methanol Plant

Utilities 2

compression

CO

2

At this point it is worth mentioning that several reports are available on coal/biomass or

municipal solid waste gasification with plasma. The biggest advantage here is that the molten

slag, which comes out of plasma gasifiers, typically operating at 3000 C, are vitreous when

0

solidified. Hence no toxic chemicals leach out from the vitrified mass. Also the overall power

requirement is quite low, compared to incineration [4, 5, 6, 7].

Considering the quality of Indian coal, fluid bed gasifiers with high pressure operation are

most suitable for immediate consideration, while for long term plans, we may explore the

development of plasma gasifiers.

2.1.2.2

SYNGAS FROM BIOGAS

Biogas is the product from digestion of biodegradable non cellular material such as food or

animal waste, including sewage sludge. The average composition of the biogas from anaerobic

digester is about 65 +/- 10% methane; the balance is carbon dioxide with a little hydrogen. The

carbon dioxide may be separated and the methane is used as natural gas in the reformer. In

view of the fact that the biogas contains a fair amount of carbon dioxide, it is possible to convert

it to syngas by dry reforming also.

Production of biogas can be economically done without much investment and the product gas is

reformed to syngas. However this anaerobic digestion is suitable only for certain specific types

of biomass such as agricultural waste, manure, municipal waste, plant material, sewage, green

waste, food waste, cake after oil extraction etc. Landfill gas is also biogas and easily reformed

to syngas. There are many installations for making methanol/DME in small scale from biogas.

With the recent growth of biodiesel production, large amount of oil cake is available. This

could be easily used in bio-methanation units along with other easily bio digestible materials

to produce biogas.

Methanol and DME Production: Survey and Roadmap | 2017 31