Page 37 - demo

P. 37

PROCESS & TECHNOLOGY FOR METHANOL AND DME

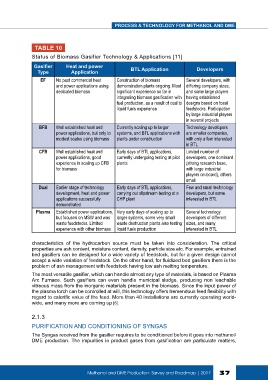

TABLE 10

Status of Biomass Gasifier Technology & Applications [11]

Gasifier Heat and power BTL Application Developers

Type Application

EF No past commercial heat Construction of biomass Several developers, with

and power applications using demonstration plants ongoing. Most differing company sizes,

dedicated biomass significant experience so far in and some large players

integrating biomass gasification with having established

fuel production, as a result of coal to designs based on fossil

liquid fuels experience feedstocks. Participation

by large industrial players

in several projects

BFB Well established heat and Currently scaling up to larger Technology developers

power applications, but only to systems, and BTL applications with are smaller companies,

modest scales using biomass plants under construction with only a few interested

in BTL

CFB Well established heat and Early days of BTL applications, Limited number of

power applications, good currently undergoing testing at pilot developers, one dominant

experience in scaling up CFB plants (strong research base,

for biomass with large industrial

players on-board), others

small

Dual Earlier stage of technology Early days of BTL applications, Few and small technology

development, heat and power carrying out slipstream testing at a developers, but some

applications successfully CHP plant interested in BTL

demonstrated

Plasma Established power applications, Very early days of scaling up to Several technology

but focused on MSW and was larger systems, some very small developers of different

waste feedstocks. Limited waste destruction plants also testing sizes, and many

experience with other biomass liquid fuels production interested in BTL

characteristics of the hydrocarbon source must be taken into consideration. The critical

properties are ash content, moisture content, density, particle size etc. For example, entrained

bed gasifiers can be designed for a wide variety of feedstock, but for a given design cannot

accept a wide variation of feedstock. On the other hand, for fluidized bed gasifiers there is the

problem of ash management with feedstock having low ash melting temperature.

The most versatile gasifier, which can handle almost any type of materials, is based on Plasma

Arc Furnace. Such gasifiers can even handle municipal sludge, producing non leachable

vitreous mass from the inorganic materials present in the biomass. Since the input power of

the plasma torch can be controlled at will, this technology offers tremendous feed flexibility with

regard to calorific value of the feed. More than 40 installations are currently operating world-

wide, and many more are coming up [6].

2.1.3

PURIFICATION AND CONDITIONING OF SYNGAS

The Syngas received from the gasifier requires to be conditioned before it goes into methanol/

DME production. The impurities in product gases from gasification are particulate matters,

Methanol and DME Production: Survey and Roadmap | 2017 37