Page 9 - Pivoting Wheel Stinger™ Signature® Series

P. 9

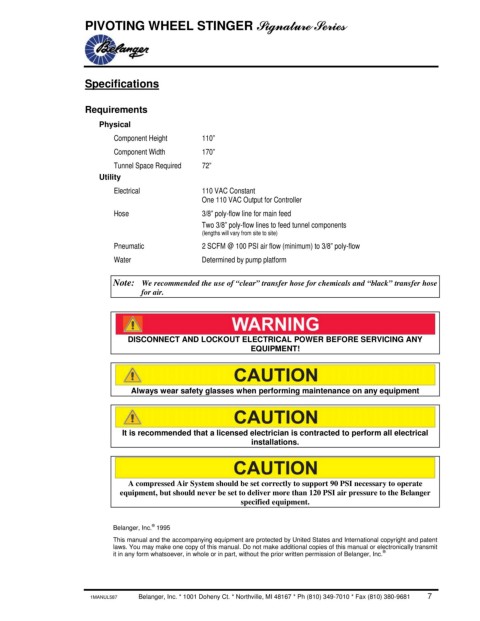

PIVOTING WHEEL STINGER Signature Series

Specifications

Requirements

Physical

Component Height 110”

Component Width 170”

Tunnel Space Required 72”

Utility

Electrical 110 VAC Constant

One 110 VAC Output for Controller

Hose 3/8” poly-flow line for main feed

Two 3/8” poly-flow lines to feed tunnel components

(lengths will vary from site to site)

Pneumatic 2 SCFM @ 100 PSI air flow (minimum) to 3/8” poly-flow

Water Determined by pump platform

Note: We recommended the use of “clear” transfer hose for chemicals and “black” transfer hose

for air.

DISCONNECT AND LOCKOUT ELECTRICAL POWER BEFORE SERVICING ANY

EQUIPMENT!

Always wear safety glasses when performing maintenance on any equipment

It is recommended that a licensed electrician is contracted to perform all electrical

installations.

A compressed Air System should be set correctly to support 90 PSI necessary to operate

equipment, but should never be set to deliver more than 120 PSI air pressure to the Belanger

specified equipment.

®

Belanger, Inc. 1995

This manual and the accompanying equipment are protected by United States and International copyright and patent

laws. You may make one copy of this manual. Do not make additional copies of this manual or electronically transmit

it in any form whatsoever, in whole or in part, without the prior written permission of Belanger, Inc.

®

1MANUL587 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (810) 349-7010 * Fax (810) 380-9681 7