Page 18 - Tire Washer

P. 18

TIRE WASHER

Maintenance

Daily

Inspect Tire brush for missing bristles, loose bolts or bent shaft that may cause wobbling, and worn

bearings.

Monthly

Inspect Tire brush for damage prior to greasing

Note: Before GREASING and after GREASING wipe off all bearing seal surfaces and Zerks.

Grease should only be applied until water is pushed out and bearings seals start to swell.

Grease arm pivot bearings (8 per side).

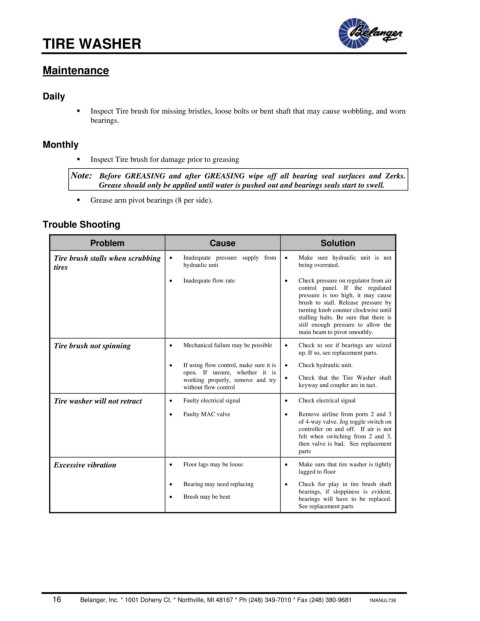

Trouble Shooting

Problem Cause Solution

Tire brush stalls when scrubbing • Inadequate pressure supply from • Make sure hydraulic unit is not

tires hydraulic unit being overrated.

• Inadequate flow rate • Check pressure on regulator from air

control panel. If the regulated

pressure is too high, it may cause

brush to stall. Release pressure by

turning knob counter clockwise until

stalling halts. Be sure that there is

still enough pressure to allow the

main beam to pivot smoothly.

Tire brush not spinning • Mechanical failure may be possible • Check to see if bearings are seized

up. If so, see replacement parts.

• If using flow control, make sure it is • Check hydraulic unit.

open. If unsure, whether it is

working properly, remove and try • Check that the Tire Washer shaft

without flow control keyway and coupler are in tact.

Tire washer will not retract • Faulty electrical signal • Check electrical signal

• Faulty MAC valve • Remove airline from ports 2 and 3

of 4-way valve. Jog toggle switch on

controller on and off. If air is not

felt when switching from 2 and 3,

then valve is bad. See replacement

parts

Excessive vibration • Floor lags may be loose • Make sure that tire washer is tightly

lagged to floor

• Bearing may need replacing • Check for play in tire brush shaft

bearings, if sloppiness is evident,

• Brush may be bent bearings will have to be replaced.

See replacement parts

16 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL738