Page 23 - Titan VPS™

P. 23

TITAN VPS™

Maintenance

Manifold Gasket Replacement

If for any reason the gaskets need to be replaced on the stated pieces of equipment, the following

guidelines can make the task more manageable.

Note: When moving a Triple Manifold Arch, always use new gaskets.

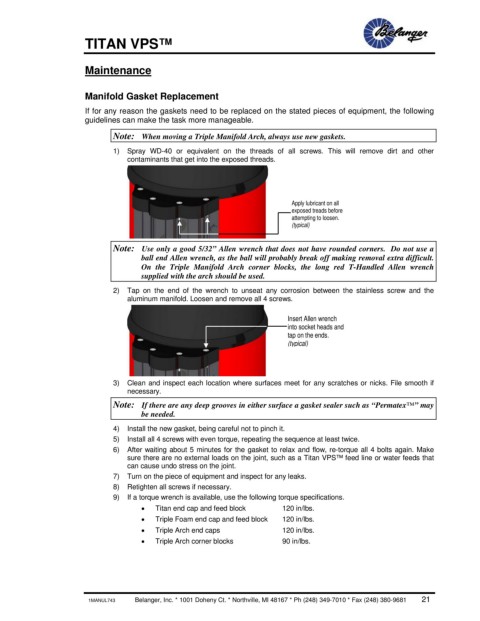

1) Spray WD-40 or equivalent on the threads of all screws. This will remove dirt and other

contaminants that get into the exposed threads.

Apply lubricant on all

exposed treads before

attempting to loosen.

(typical)

Note: Use only a good 5/32” Allen wrench that does not have rounded corners. Do not use a

ball end Allen wrench, as the ball will probably break off making removal extra difficult.

On the Triple Manifold Arch corner blocks, the long red T-Handled Allen wrench

supplied with the arch should be used.

2) Tap on the end of the wrench to unseat any corrosion between the stainless screw and the

aluminum manifold. Loosen and remove all 4 screws.

Insert Allen wrench

into socket heads and

tap on the ends.

(typical)

3) Clean and inspect each location where surfaces meet for any scratches or nicks. File smooth if

necessary.

Note: If there are any deep grooves in either surface a gasket sealer such as “Permatex™” may

be needed.

4) Install the new gasket, being careful not to pinch it.

5) Install all 4 screws with even torque, repeating the sequence at least twice.

6) After waiting about 5 minutes for the gasket to relax and flow, re-torque all 4 bolts again. Make

sure there are no external loads on the joint, such as a Titan VPS™ feed line or water feeds that

can cause undo stress on the joint.

7) Turn on the piece of equipment and inspect for any leaks.

8) Retighten all screws if necessary.

9) If a torque wrench is available, use the following torque specifications.

• Titan end cap and feed block 120 in/lbs.

• Triple Foam end cap and feed block 120 in/lbs.

• Triple Arch end caps 120 in/lbs.

• Triple Arch corner blocks 90 in/lbs.

1MANUL743 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 21