Page 8 - stanochny park

P. 8

METALWORKING EQUIPMENT AND TOOLS METALWORKING EQUIPMENT AND TOOLS

Uneven movement of the en movement of the the eccentricities of both shafts are directed

Unev

in different directions, additional tension of

support of the MK-3002 -3002 the V-belt occurs, and when the eccentricities

support of the MK

of both shafts are directed to each other, the

lathe tension of the V-belt is weakened. This period

lathe

of time corresponds to 11 spindle revolutions.

Thus, torsional vibrations of the spindle in time

THREADED are caused by the low accuracy of the V-belt

THREADED CONNECTIONS GOT A WIDE DISTRIBUTION IN CONNECTIONS GOT A WIDE DISTRIBUTION IN

MODERN MACHINES. WHEN USING THREADED CONNECTIONS . WHEN USING THREADED CONNECTIONS pulleys.

MODERN MACHINES

AS SCREWS OF A SCREW-NUT, REQUIREMENTS FOR THE ACCURACY S SCREWS OF A SCREW-NUT, REQUIREMENTS FOR THE ACCURACY

A Figure 4 shows the curves of non-

OF MOVING A NUT, DEPENDING ON THE ANGLE OF TURN OF MOVING A NUT, DEPENDING ON THE ANGLE OF TURN OF

OF uniformity of rotation of the lead screw per

THE SCREW ARE INCREA

THE SCREW ARE INCREASEDSED revolution at idle and during cutting. The

graphs show that the torsional vibrations of

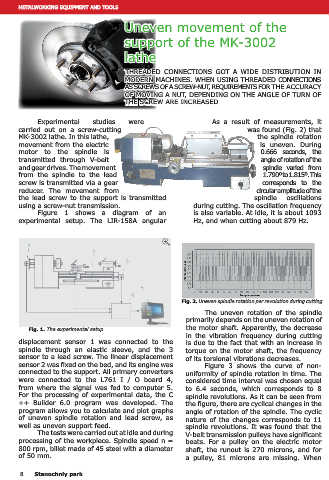

Experimental studies were As a result of measurements, it the lead screw have a pronounced harmonic

carried out on a screw-cutting was found (Fig. 2) that character. The frequency of torsional vibrations

MK-3002 lathe. In this lathe, the spindle rotation of the lead screw at idle is 455 Hz, and when

movement from the electric is uneven. During cutting is 494 Hz.

motor to the spindle is 0.666 seconds, the

transmitted through V-belt angle of rotation of the Fig. 4. The uneven rotation of the lead screw per revolution:

a - idle mode; b - cutting mode.

and gear drives. The movement spindle varied from

from the spindle to the lead 1.790º to 1.815º. This

screw is transmitted via a gear corresponds to the

reducer. The movement from circular amplitude of the

the lead screw to the support is transmitted spindle oscillations

using a screw-nut transmission. during cutting. The oscillation frequency

Figure 1 shows a diagram of an is also variable. At idle, it is about 1093

experimental setup. The LIR-158A angular Hz, and when cutting about 879 Hz.

Fig. 3. Curve of uneven spindle rotation in time during cutting

The magnitude of the amplitude of

torsional vibrations in these cases is almost Fig. 5. The unevenness of the support in the mode: a - idle;

b - cutting.

the same and does not exceed 0.0750°, which

speaks in favor of the fact that the gear reducer, Table 1.

Fig. 2. Uneven spindle rotation per revolution during cutting. consisting of seven stages, does not make Type of gear Idling Cutting

The uneven rotation of the spindle significant changes in the uneven rotation of V-belt 0,02 0,02

primarily depends on the uneven rotation of the lead screw. Gear spindle 0,44 0,44

Fig. 1. The experimental setup. the motor shaft. Apparently, the decrease As can be seen from fig. 5, the uneven Toothed spindle 0,40 0,40

in the vibration frequency during cutting feed of the support at idle and during cutting

displacement sensor 1 was connected to the is due to the fact that with an increase in has significant differences. At idle, monotonic Screw nut 10,00 24,0

spindle through an elastic sleeve, and the 3 torque on the motor shaft, the frequency vibrations are observed, which consist of two

V.V. Yurkevich,

sensor to a lead screw. The linear displacement of its torsional vibrations decreases. types - 5 and 10 microns. When cutting, the Ph.D., professor of MSTU Stankin

sensor 2 was fixed on the bed, and its engine was Figure 3 shows the curve of non- amplitude of oscillations of the feed of the

connected to the support. All primary converters uniformity of spindle rotation in time. The caliper sharply changes in time and in the References:

were connected to the L761 I / O board 4, considered time interval was chosen equal considered area is mainly 24 microns. However, 1. Yurkevich V.V. Determining the accuracy of

from where the signal was fed to computer 5. to 6.4 seconds, which corresponds to 8 in one place, the amplitude increases to 32 μm. processing on a lathe. Machine tools and tools 1999. No. 4,

For the processing of experimental data, the C spindle revolutions. As it can be seen from It can be assumed that these vibrations are p. 15-17.

2. Yurkevich V.V. Monitoring and diagnostics of

++ Builder 6.0 program was developed. The the figure, there are cyclical changes in the the result of a foreign body entering between the shaping process during processing on lathes. Control.

program allows you to calculate and plot graphs angle of rotation of the spindle. The cyclic the carriage and the bed guides. Diagnostics, 2005, No. 1, p. 45 - 50.

3. Yurkevich V.V. Determining the causes of uneven

of uneven spindle rotation and lead screw, as nature of the changes corresponds to 11 In order to assess what error is introduced feed of the support of the MK-3002 lathe. Handbook,

well as uneven support feed. spindle revolutions. It was found that the into the support feed by each gear included in Engineering Journal, 2006, No. 11, p. 37 - 40.

The tests were carried out at idle and during V-belt transmission pulleys have significant the motion transmission system from the main 4. Sabirov F.S., Savinov S.Yu. Diagnosis and

processing of the workpiece. Spindle speed n = beats. For a pulley on the electric motor electric motor to the support, the errors of accuracy control of feed drives of multi-axis CNC machine

tools // Measuring technique. 2011, No. 8, p. 20-22.

800 rpm, billet made of 45 steel with a diameter shaft, the runout is 270 microns, and for these gears were calculated in microns, given

of 50 mm. a pulley, 81 microns are missing. When to the support feed, tab. 1

8 Stanochniy park Stanochniy park 9