Page 11 - stanochny park

P. 11

METALWORKING EQUIPMENT AND TOOLS METALWORKING EQUIPMENT AND TOOLS

Continuous and shaped casting conveyor is not a string of removal of it from this filter an endless (annular) moving

separate shapes, but one in the wall or bottom of the tape, has filters at the junction

of metal products in vacuum casting mold, for example, in trough regulates the strength with the tape and constant

the form of a gutter with sand of the mold. At the same time, communication

through

a

sand molds on a vertically closed conveyor in the casting and solidification rotating drum with a vacuum

belt. Moreover, in patents section of the casting, this pump. The vacuum control

for continuous casting, such strength is maintained to the device opens the vacuum

a trench is usually called a maximum, in the molding wire filters on this tape and

The technology of casting in vacuum sand forms movable mold lined with sand. section — sufficient to perform connects the cladding sand

without a binder was invented in Japan in 1971 by AkitA, With the continuous movement the casting cavities and to the vacuum when the tape

it was called V-process or vacuum-film molding (VFM) of this trough, in the course delivering them to the casting enters a strictly defined area,

[1]. Today, the VFM has in fact moved from the category of movement, a layer of dry section, in the cooling section beyond which the filters are

sand is first poured into it, of the solidified casting the closed by spring mechanisms,

of special castings to the main casting technologies. This

method has violated the traditions of quartz sand mold and then, simultaneously with mold is not evacuated. The and the vacuum does not

technology with a binder, bringing to the foundries a sealing with a synthetic film of vacuum system operates only enter the sand.

more environmentally friendly and resource-saving, but the sand layer, casting cavities on a relatively short conveyor The sand form moving

at the same time knowledge-intensive process. are molded in it, connecting zone. The conveyor moves, but on the conveyor can be

the vacuum to the conveyor in this zone remains motionless considered as a single one or

the area where it is necessary due to the functioning of the as a lower half-form [2 - 6].

to keep the form in a stone evacuation system of moving For the second case, methods

Despite a fairly large number of publications and hundreds of patents on VFM (including

objects, the known designs of have been developed for

dozens of patents of the domestic scientific and technical school on the theory and technology state. Since the vacuum due which are used on hundreds of forming the upper half-mold

of molds), methods of casting in vacuum molds are among the leaders in the dynamics of to the difficult filtration in the operating VFM conveyors with and assembling it from the

publications of innovations and varieties, gradually expanding the volume, nomenclature and

geography of production of cast products. At the same time, the high quality of castings obtained sandy medium at a distance traditional forms in paired bottom when finally forming

a continuously moving sand

of 0.35 ... 0.40 m from the flasks.

by this method is close in accuracy to injection molding, and in terms of surface quality - to

die casting. In addition, the VFM shows an example of successful solution of the environmental vacuum source - the mesh One example of the layer as a mold with one along

filter - decreases by 2.0 ... 2.5 design of such a mold vacuum the conveyor or with many

problems of the foundry due to the use of a minimum of polymers in the casting molds (only times [1], then the values of system is described in the working cavities. After pouring

a synthetic film with a thickness of 0.05 ... 0.1 mm and a binder for flame retardant paint) in

combination with the pumping of gases from the casting mold with a vacuum pump. the vacuum on the filter, the invention [7]. It is made in the metal and sufficient

degree of depressurization, the form of a flexible vacuum hardening of the casting,

The conveyor equipment described in this article is the result of innovative developments

compaction of sand and wire, which is located along the softening of the mold is

by specialists of the Physics and Technology

Institute of Metals and Alloys (FTIMS) of the

National Academy of Sciences of Ukraine (Kiev)

in the process of improving the technology of

casting into vacuum molds under the guidance

of prof. O.I. Shinsky. Prospects for further

development associated with a combination of

advantages vacuum molds with one-time casting

of foam or ice (cryo-vacuum technology).

The high fluidity of dry sand during

vibration in the process of molding allows

us to consider it as a pseudo-fluid that easily

(without the powerful sealing machines inherent

in traditional sand-clay molding) fills the space

around the often complex shaped surfaces of

casting models (both reusable and disposable)

during the manufacturing process which usually

lasts a few minutes. Moreover, the stone-like

state of sand during evacuation of the mold (a pressure of the order of 0.5 atm ≈ 50 kPa) is

necessary only from the moment of molding to pouring the mold and subsequent solidification

of the casting to a state where it is able to keep its geometry in the sandy environment. In

other cases, evacuation is not required. The rational regulation of mold strength when creating

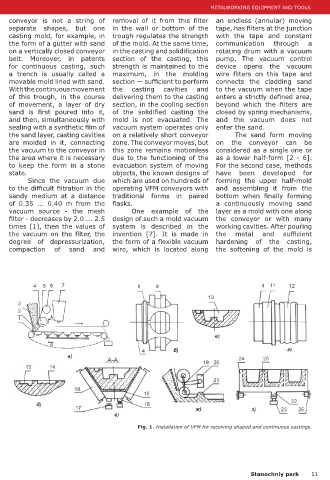

continuous installations combining transport operations with technological ones served the Fig. 1. Installation of VFM for receiving shaped and continuous castings.

purpose of the developments described in this article.

Based on the principle of minimizing the duration of mold evacuation using sand fluidity, a

series of designs of VFM lines were constructed and published earlier [2–6], in which a moving

10 Stanochniy park Stanochniy park 11