Page 13 - NSFP Waste to Energy Solution 080218

P. 13

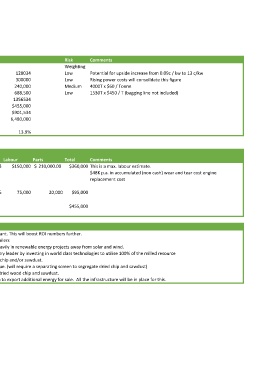

Rising power costs will consolidate this figure Potential for upside increase from 0.09c / kw to 13 c/kw 1530T x $450 / T (bagging line not included) This is a max. labour estimate. $48K p.a. in accumulated (non cash) wear and tear cost engine

Comments 4000T x $60 / Tonne Comments replacement cost

Weighting Medium $360,000 $95,000 $455,000

Risk Low Low Low Total

210,000.00 20,000

Parts $ 4. NSFP has the opportunity to become an industry leader by investing in world class technologies to utilise 100% of the milled resource 8. Add additional pellet gasifiers onto the system to export additional energy for sale. All the infrastructure will be in place for this.

128034 300000 240,000 688,500 1356534 $455,000 $901,534 6,480,000 13.9% $150,000 75,000 6. Dry on site saw dust for additional sales revenue. (will require a separating screen to segregate dried chip and sawdust)

Labour 3. CEFC have recently been directed to invest heavily in renewable energy projects away from solar and wind.

3 1.5

No. workers 1. Obtain ARENA co‐funding for on site energy plant. This will boost ROI numbers further. 2. Negotiate a stronger FIT energy price with retailers 5. Increase pellet production using surplus dried chip and/or sawdust. 7. Manufacture briquettes on site using surplus dried wood chip and sawdust.

Revenue streams Electrical income external Electrical income internal Dried chip to 12%. 4000 Tonnes Pellet sales surplus bulk pellets Total revenue Less OpEx Total free cash generated Investment amount ROI OpEx Costs ‐ annual Gasifiers: 3 units Nova press Total OpEx Opportunities

NSFP‐ Investment Returns

MW hrs 3465 1042.4 2422.6 1000 300 300000 1422.6 128034 428034

1530

Projected savings after CapEx Stage 1 energy generation less extra energy consumption Surplus energy generated Current energy consumed from grid Current energy cost / MW Total current energy cost Surplus energy exported Revenue at $90 / Mw Total electrical energy savings