Page 23 - Wurth Total Catalogue

P. 23

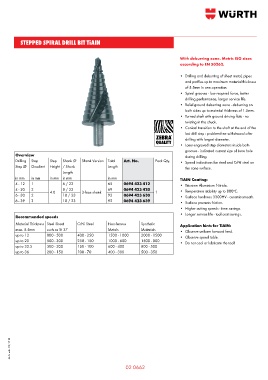

STEPPED SPIRAL DRILL BIT TiAIN

With deburring zone. Metric ISO sizes

according to EN 50262.

• Drilling and deburring of sheet metal, pipes

and profiles up to maximum material thickness

of 5.5mm in one operation.

• Spiral grooves - low required force, better

drilling performance, longer service life.

• Relief-ground deburring zone - deburring on

both sides up to material thickness of 1.5mm.

• Turned shaft with ground driving flats - no

twisting in the chuck.

• Conical transition to the shaft at the end of the

last drill step - problem-free withdrawal after

drilling with largest diameter.

• Laser-engraved step diameters inside both

grooves - indicated current size of bore hole

Overview during drilling.

Drilling Step Step Shank Ø Shank Version Total Art. No. Pack Qty. • Speed indications for steel and CrNi steel on

Step Ø Gradient Height / Shank Length the cone surface.

Length

in mm in mm in mm in mm in mm TiAIN Coating:

4 - 12 1 6 / 23 65 0694 423 412 • Titanium Aluminium Nitride.

4 - 20 2 4.0 8 / 23 3-face shank 69 0694 423 420 1 • Temperature stability up to 800 C.

o

6 - 30 2 10 / 23 92 0694 423 630 • Surface hardness 3300HV - ceramic-smooth.

6 - 39 3 10 / 23 92 0694 423 639 • Surface prevents friction.

• Higher cutting speeds - time savings.

• Longer service life - tool cost savings.

Recommended speeds

Material Thickness Steel Sheet CrNi Steel Non-ferrous Synthetic Application hints for TiAIN:

max. 5.5mm such as St 37 Metals Materials • Observe uniform forward feed.

up to 12 800 - 500 400 - 250 1500 - 1000 2000 - 1500 • Observe speed table.

up to 20 500 - 300 250 - 150 1000 - 600 1500 - 800 • Do not cool or lubricate the tool!

up to 32.5 300 - 200 150 - 100 600 - 400 800 - 500

up to 36 200 - 150 100 - 70 400 - 300 500 - 350

AUS. pub. 02/17 ©

02 0662