Page 25 - Wurth Total Catalogue

P. 25

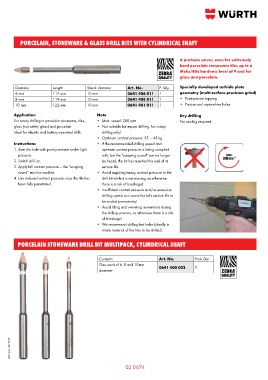

PORCELAIN, STONEWARE & GLASS DRILL BITS WITH CYLINDRICAL SHAFT

A problem solver, even for extremely

hard porcelain stoneware tiles up to a

Mohs/Ritz hardness level of 9 and for

glass and porcelain.

Diameter Length Shank diameter Art. No. P. Qty. Specially developed carbide plate

6 mm 117 mm 10 mm 0641 406 011 1 geometry (multi-surface precision grind)

8 mm 119 mm 10 mm 0641 408 011 1 • Point-precise tapping

10 mm 122 mm 10 mm 0641 401 011 1 • Precise and rupture-free holes

Application Note Dry drilling

For rotary drilling in porcelain stoneware, tiles, • Max. speed: 200 rpm No cooling required.

glass (not safety glass) and porcelain. • Not suitable for impact drilling. For rotary

Ideal for electric and battery-operated drills. drilling only!

• Optimum contact pressure: 35 – 45 kg

Instructions • If the recommended drilling speed and

1. Start the hole with point precision under light optimum contact pressure is being complied

pressure. with, but the "scraping sound" can no longer

2. Switch drill on. be heard, the bit has reached the end of its

3. Apply full contact pressure – the "scraping service life.

sound" must be audible. • Avoid applying heavy contact pressure to the

4. Use reduced contact pressure once the tile has drill bit while it is not moving, as otherwise

been fully penetrated. there is a risk of breakage!

• Insufficient contact pressure and/or excessive

drilling speed can cause the bit's service life to

be ended prematurely!

• Avoid tilting and swiveling movements during

the drilling process, as otherwise there is a risk

of breakage!

• We recommend drilling test holes (ideally in

waste material of the tiles to be drilled).

PORCELAIN STONEWARE DRILL BIT MULTIPACK, CYLINDRICAL SHAFT

Contents Art. No. Pack Qty.

One each of 6, 8 and 10mm

diameter 0641 400 003 1

AUS. pub. 03/15 ©

02 0674