Page 286 - Wurth Total Catalogue

P. 286

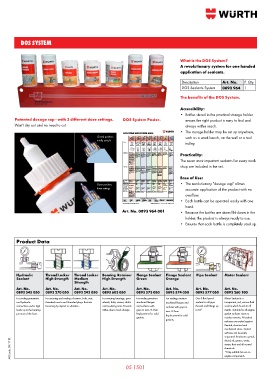

DOS SYSTEM

What is the DOS System?

A revolutionary system for one handed

application of sealants.

Description Art. No. P. Qty.

DOS Sealants System 0893 964 1

The benefits of the DOS System.

Accessibility:

• Bottles stored in the practical storage holder

Patented dosage cap - with 3 different dose settings. DOS System Poster. means the right product is easy to find and

Won't dry out and no need to cut. always within reach.

• The storage holder may be set up anywhere,

DOS SYSTEM APPLICATION GUIDE

Closed position, Motor Sealant Thread Locker Thread Locker Bearing Retainer Sealant Flange Flange Sealant Sealant Pipe Hydraulic Sealant such as a work bench, on the wall or a tool

totally airtight

Product Motor Thread Locker Thread Locker Bearing Flange Flange Pipe Hydraulic

Sealant High Strength Medium Retainer Sealant Sealant Sealant Sealant trolley.

Strength High Strength Green Orange

Art. No. Art. No. Art. No. Art. No. Art. No. Art. No. Art. No. Art. No.

0893 260 100 0893 270 050 0893 243 050 0893 603 050 0893 573 050 0893 574 050 0893 577 050 0893 545 050

Application: Motor Sealant is a For securing and For securing and For securing bearings, For sealing precision For sealing precision Gas & fluid proof For sealing pneumatic

transparent, red, viscous sealing of screws, sealing of screws, gear wheels, bolts, sealant for all pipe and hydraulic

machined flanges

machined flanges

fluid sealant which bonds bolts, nuts, threaded bolts, nuts, threaded screws, shafts and and surfaces with and surfaces with threads and fittings up connections under Practicality:

to all metals. Suitable for inserts and threaded inserts and threaded auxiliary joints. Replacement for solid Replacement for solid to R3”. high loads up to the

gaps to max. 0.3mm. gaps to max. 0.5mm.

all engine gasket surfaces plugs. Restricts plugs. Restricts Prevents rattles due to gaskets. gaskets. bursting pressure of

since no residue remains. loosening by impact loosening by impact load change. the hose.

All sealed surfaces are or vibration. or vibration.

sealed against thermal,

chemical and mechanical

stress. Sealed surfaces

can be easily separated. The seven most important sealants for every work

Resistant to petrol, diesel,

oil, grease, water, steam,

frost and all normal

chemicals.

*Only suitable for use on

engine components.

Properties: A product that adheres Universal product A commonly used Universal product for Particularly suitable Particularly suitable Excellent resistance Excellent resistance shop are included in the set.

to most surfaces. It is for all threads and product, providing heavily stressed joints. where a good where a good to chemicals, gas, to chemicals, gas,

permanently pliable and cylindrical parts which excellent protection High tear-resistance. coverage is essential coverage is essential liquids, fuels and liquids, fuels and

resistant to vibration. As would not normally be against oil, water and Can be used in small e.g. with complicated e.g. with complicated hydraulic fluids. hydraulic fluids.

the product only has to released again. heat. spaces between castings, narrow links castings, narrow links Fast curing even at

applied thinly to one side Can be released with Will harden even at joined surfaces. and smooth surfaces. and smooth surfaces. low temperatures.

it is very economical. It special tools and/or very low temperature. Excellent resistance to An easily detached An easily detached Can be applied on

can also be used as a heat. low adhesion joint, low adhesion joint,

replacement for solid Can be released with media. which is particularly which is particularly slightly oily surfaces,

gaskets. normal tools. flexible. flexible. no need for time

consuming degreasing

Highly suitable for of threads.

larger and rougher

Ease of Use:

machined surfaces.

Chemical Basis: Epoxy resin Dimethylacrylate Dimethylacrylate Dimethylacrylate Dimethylacrylate Dimethylacrylate Dimethylacrylate Dimethylacrylate

Colour: 5,000 – 13,200 400 - 600 5,000 - 7,000 100 - 150 40,000 - 60,000 35,000 - 100,000 20,000 - 80,000 1,500 - 2,000

Transparent Red

Fluorescent Blue

Green

Fluorescent Green

Green

Fluorescent Yellow

Fluorescent Orange

Violet

Viscosity in mPas: 1 year 1 year 1 year 1 year 1 year 1 year 1 year 1 year • The revolutionary "dosage cap" allows

Stability in storage:

Open position, Full strength at 25ºC: +80 o C=6hrs, +180 o C=5hrs 6 hours >30Nm 3 hours 21Nm 6 - 24 hours 6 - 24 hours 6 - 24 hours 3 hours 15 - 20Nm 12 - 24 hours

–

8 - 12Nm

17 - 22Nm

2-3Nm

Break loose resistance:

–

Operating pressure: 700 bar (10,290psi) – – – – – – – 2 - 4 N/mm 2 – 8 - 10 N/mm 2 300 bar (4410psi) 200 bar (2940psi)

–

–

–

Tensile strength:

three settings Temp. resistance: -50 o C to +280 o C -55 o C to +150 o C -55 o C to +150 o C -55 o C to +150 o C -55 o C to +150 o C -55 o C to +150 o C -55 o C to +150 o C -55 o C to +150 o C

up to 0.5mm

up to 0.25mm

up to 0.3mm

up to 0.15mm

0.5mm

0.15mm

up to 0.15mm

approx 2mm

Max. gap bridging:

Max. thread joint: – M20 M36 M12 – – R3” (M80) R3/4” accurate application of the product with no

Max. glue gap: approx 2mm – – – 0.3mm 0.5mm – –

Instructions for use: Clean and dry the surfaces Clean add dry threads, applying a small amount Clean and dry all surfaces to be sealed with a suitable solvent (ie. Brake Cleaner - 0890 108 7). Apply a small amount

to be sealed.

of Hydraulic Sealant to

Apply a thin layer of Sealant to one side only and assemble parts immediately.

of Thread Lock. Tighten to specifications.

Apply a thin layer of the threads and tighten to

material on one side and specifications.

leave for 5-20min to air, then

join two surfaces. Thermal overflow.

hardening possible

from +60 o C. It is relatively

easy to separate the joined

parts if necessary.

RESISTANCE TABLE FOR DOS-SYSTEM

• Kerosene • Alcohols • Formic Acids • Ethelacetate • Acetone • Petrol • Alkaline Solutions • Phosphoric acid (10%) • Each bottle can be operated easily with one

• Diesel • Jet Fuel • Aviation Spirit • Frost protection • Gear oil • Heating oil • Hydraulic oil • Solvents (chlorinated)

• Engine oil • Oils • Xilene • Steam • Coolants • Brake Fluid

Article No. 0893 964 001/ Job No. 391110 - AUS/Revised/Reprint: 2/11 Wurth Australia Pty. Ltd. - T: 1300 65 77 65 - Contact us today

hand.

Art. No. 0893 964 001 • Because the bottles are stored lid-down in the

holder, the product is always ready to use.

• Ensures that each bottle is completely used up.

Product Data

Hydraulic Thread Locker Thread Locker Bearing Retainer Flange Sealant Flange Sealant Pipe Sealant Motor Sealant

Sealant High Strength Medium High Strength Green Orange

Strength

Art. No. Art. No. Art. No. Art. No. Art. No. Art. No. Art. No. Art. No.

0893 545 050 0893 270 050 0893 243 050 0893 603 050 0893 573 050 0893 574 050 0893 577 050 0893 260 100

For sealing pneumatic For securing and sealing of screws, bolts, nuts, For securing bearings, gear For sealing precision For sealing precision Gas & fluid proof Motor Sealant is a

and hydraulic threaded inserts and threaded plugs. Restricts wheels, bolts, screws, shafts machined flanges machined flanges and sealant for all pipe transparent, red, viscous fluid

connections under high loosening by impact or vibration. and auxiliary joints. Prevents and surfaces with surfaces with gaps to threads and fittings up sealant which bonds to all

loads up to the bursting rattles due to load change. gaps to max. 0.3mm. max. 0.5mm. to R3”. metals. Suitable for all engine

pressure of the hose. Replacement for solid Replacement for solid gasket surfaces since no

gaskets. residue remains. All sealed

gaskets.

surfaces are sealed against

thermal, chemical and

mechanical stress. Sealed

surfaces can be easily

separated. Resistant to petrol,

AUS. pub. 08/17 © steam, frost and all normal

diesel, oil, grease, water,

chemicals.

*Only suitable for use on

engine components.

05 1501