Page 310 - Wurth Total Catalogue

P. 310

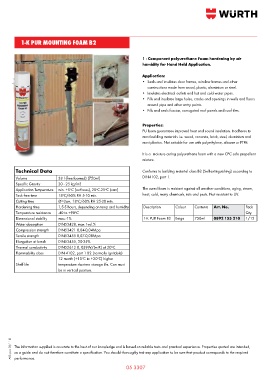

1-K PUR MOUNTING FOAM B2

1 - Component polyurethane Foam hardening by air

humidity for Hand Held Application.

Application:

• Seals and insulates door frames, window frames and other

constructions made from wood, plastic, aluminium or steel.

• Insulates electrical outlets and hot and cold water pipes.

• Fills and insulates large holes, cracks and openings in walls and floors

around pipe and other entry points.

• Fills and seals fascias, corrugated roof panels and roof tiles.

Properties:

PU foam guarantees improved heat and sound insulation. It adheres to

most building materials i.e. wood, concrete, brick, steel, aluminium and

most plastics. Not suitable for use with polyethylene, silicone or PTFE.

It is a moisture curing polyurethane foam with a new CFC safe propellent

mixture.

Technical Data Conforms to building material class B2 (Self-extinguishing) according to

Volume 38 l (free foamed) (750ml) DIN4102, part 1.

Specific Gravity 20 - 25 kg/m3

Application Temperature min. +5 C (surfaces), 20 C-25 C (can) The cured foam is resistant against all weather conditions, aging, steam,

o

o

o

Tack free time 18 C/60% RH 5-10 min. heat, cold, many chemicals, rats and pests. Not resistant to UV.

o

Cutting time Ø=3cm, 18 C/60% RH 25-30 min.

o

Hardening time 1,5-5 hours, depending on temp and humidity Description Colour Contents Art. No. Pack

Temperature resistance -40 to +90 C Qty.

o

Dimensional stability max.-1% 1-K PUR Foam B2 Beige 750ml 0892 155 210 1/12

Water absorption DIN53428, max.1vol.%

Compression strength DIN53421 0,04-0,04Mpa

Tensile strength DIN53455 0,07-0,08Mpa

Elongation at break DIN53455, 20-25%

o

Thermal conductivity DIN52612 0, 039W/(m K) at 20 C

Flammability class DIN 4102, part 1 B2 (normally ignitable)

12 month (+10 C to +20 C) higher

o

o

Shelf life temperature shortens storage life. Can must

be in vertical position.

AUS. pub. 02/11 © The information supplied is accurate to the best of our knowledge and is based on reliable tests and practical experience. Properties quoted are intended,

as a guide and do not therefore constitute a specification. You should thoroughly test any application to be sure that product corresponds to the required

performance.

05 3307