Page 35 - William Brown 2017

P. 35

Making Diary

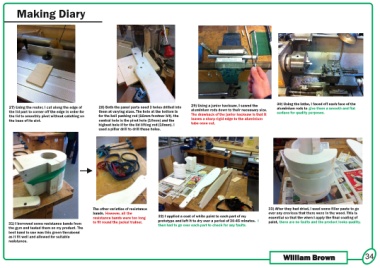

27) Using the router, I cut along the edge of 28) Both the panel parts need 3 holes drilled into 29) Using a junior hacksaw, I sawed the 30) Using the lathe, I faced off each face of the

aluminium rods to give them a smooth and flat

the lid part to corner off the edge in order for them at varying sizes. The hole at the bottom is aluminium rods down to their necessary size. surface for quality purposes.

the lid to smoothly pivot without catching on for the ball pushing rod (16mm forstner bit), the The drawback of the junior hacksaw is that it

the base of its slot. central hole is the pivot hole (10mm) and the leaves a sharp rigid edge to the aluminium

highest hole if for the lid lifting rod (10mm). I tube once cut.

used a pillar drill to drill these holes.

The other varieties of resistance 33) After they had dried, I used some filler paste to go

bands. However, all the over any crevices that there were in the wood. This is

resistance bands were too long 32) I applied a coat of white paint to each part of my essential so that the when I apply the final coating of

31) I borrowed some resistance bands from to fit round the jackal trainer. prototype and left it to dry over a period of 30-45 minutes. I paint, there are no faults and the product looks quality.

then had to go over each part to check for any faults.

the gym and tested them on my product. The

best band to use was this green therabond

as it fit well and allowed for suitable

resistance.

William Brown 34