Page 36 - William Brown 2017

P. 36

Making Diary

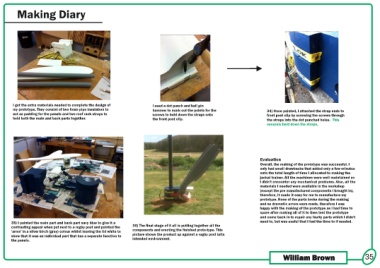

I got the extra materials needed to complete the design of I used a dot punch and ball pin

my prototype. They consist of two foam pipe insulators to hammer to mark out the points for the 34) Once painted, I attached the strap ends to

act as padding for the panels and two roof rack straps to screws to hold down the straps onto front post clip by screwing the screws through

hold both the main and back parts together. the front post clip. the straps into the dot punched holes. This

securely held down the straps.

Evaluation

Overall, the making of the prototype was successful. I

only had small drawbacks that added only a few minutes

onto the total length of time I allocated to making the

jackal trainer. All the machines were well maintained so

I didn’t encounter any mechanical problems. Also, all the

materials I needed were available in the workshop

(except the pre manufactured components I brought in),

therefore, it made it easy for me to manufacture my

prototype. None of the parts broke during the making

and no dramatic errors were made, therefore I was

happy with the making of the prototype as I had time to

spare after making all of it to then test the prototype

and come back in to repair any faulty parts which I didn’t

35) I painted the main part and back part navy blue to give it a need to, but was useful that I had the time to if needed.

contrasting appeal when put next to a rugby post and painted the 36) The final stage of it all is putting together all the

‘arms’ in a silver birch (grey) colour whilst leaving the lid white to components and erecting the finished proto-type. This

show that it was an individual part that has a separate function to picture shows the product up against a rugby post inits

the panels. intended environment.

William Brown 35