Page 268 - Natural Antioxidants, Applications in Foods of Animal Origin

P. 268

Methods and Their Applications for Measuring 247

VetBooks.ir 2. Cooked to 165 °F (74 °C) at 325 °F (163 °C) and held three hours

in a135 °F (57 °C)warming oven according to hazardous analysis

critical control point (HACCP) procedures (product abuse #1).

3. Cooked to 165 °F (74 °C), stored at 35—38 °F (2 °C–3 °C) for 48

hours then reheated (product abuse #2).

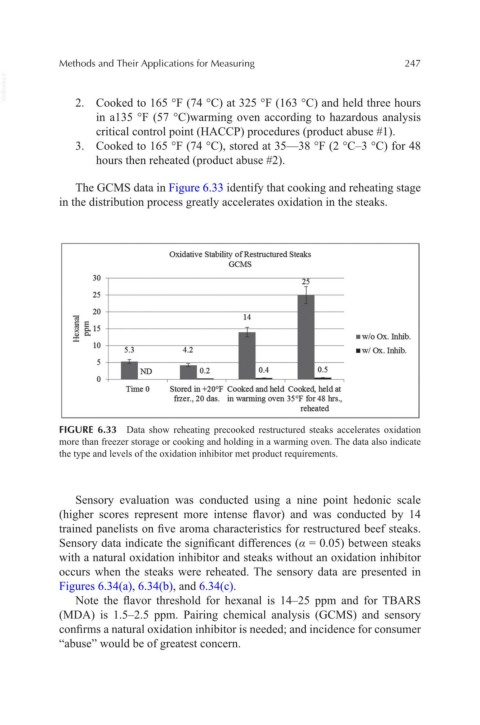

The GCMS data in Figure 6.33 identify that cooking and reheating stage

in the distribution process greatly accelerates oxidation in the steaks.

Oxidative Stability of Restructured Steaks

GCMS

30

25

'" § §..15

~ "' • w/o Ox. Inhib.

10 +--.~------.--..,-----

• w/ Ox. Inhib.

5

0

TimeO Stored in +20°F Cooked and held Cooked, held at

frzer., 20 das. in warming oven 35°F for 48 hrs.,

reheated

FIGURE 6.33 Data show reheating precooked restructured steaks accelerates oxidation

more than freezer storage or cooking and holding in a warming oven. The data also indicate

the type and levels of the oxidation inhibitor met product requirements.

Sensory evaluation was conducted using a nine point hedonic scale

(higher scores represent more intense flavor) and was conducted by 14

trained panelists on five aroma characteristics for restructured beef steaks.

Sensory data indicate the significant differences (α = 0.05) between steaks

with a natural oxidation inhibitor and steaks without an oxidation inhibitor

occurs when the steaks were reheated. The sensory data are presented in

Figures 6.34(a), 6.34(b), and 6.34(c).

Note the flavor threshold for hexanal is 14–25 ppm and for TBARS

(MDA) is 1.5–2.5 ppm. Pairing chemical analysis (GCMS) and sensory

confirms a natural oxidation inhibitor is needed; and incidence for consumer

“abuse” would be of greatest concern.