Page 176 - Small Animal Clinical Nutrition 5th Edition

P. 176

178 Small Animal Clinical Nutrition

manufacturer receives ingredients depends on the physical

VetBooks.ir makeup of the manufacturing plant and how much and what

kind of storage units are available. Most ingredient suppliers

offer multiple shipment options to best suit the needs of the

manufacturer.

Grinding

Ingredients supplied as large particles may need to be ground

before mixing (pregrinding) to enhance their nutritional and

process characteristics. Generally, the larger the particle size,

the more likely that pregrinding is necessary. A good example

of this type of ingredient is whole yellow corn. A milling

device known as a hammer mill is most often used to grind

raw materials and the final dry mix. The hammer mill is a

large capacity-milling machine that contains multiple free-

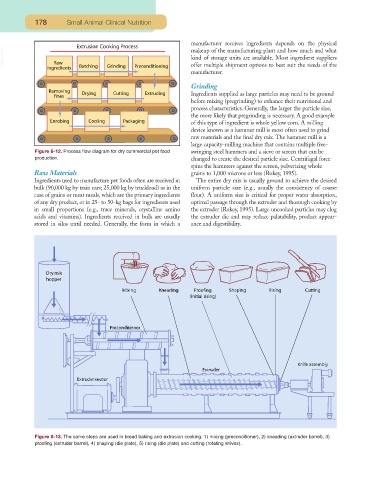

Figure 8-12. Process flow diagram for dry commercial pet food swinging steel hammers and a sieve or screen that can be

production. changed to create the desired particle size. Centrifugal force

spins the hammers against the screen, pulverizing whole

Raw Materials grains to 1,000 microns or less (Rokey, 1995).

Ingredients used to manufacture pet foods often are received in The entire dry mix is usually ground to achieve the desired

bulk (90,000 kg by train cars; 25,000 kg by truckload) as in the uniform particle size (e.g., usually the consistency of coarse

case of grains or meat meals, which are the primary ingredients flour). A uniform size is critical for proper water absorption,

of any dry product, or in 25- to 50-kg bags for ingredients used optimal passage through the extruder and thorough cooking by

in small proportions (e.g., trace minerals, crystalline amino the extruder (Rokey, 1995). Large uncooked particles may clog

acids and vitamins). Ingredients received in bulk are usually the extruder die and may reduce palatability, product appear-

stored in silos until needed. Generally, the form in which a ance and digestibility.

Figure 8-13. The same steps are used in bread baking and extrusion cooking: 1) mixing (preconditioner), 2) kneading (extruder barrel), 3)

proofing (extruder barrel), 4) shaping (die plate), 5) rising (die plate) and cutting (rotating knives).