Page 242 - Six Sigma Advanced Tools for Black Belts and Master Black Belts

P. 242

OTE/SPH

OTE/SPH

Char Count= 0

August 31, 2006

JWBK119-15

3:4

Moisture Soak Model 227

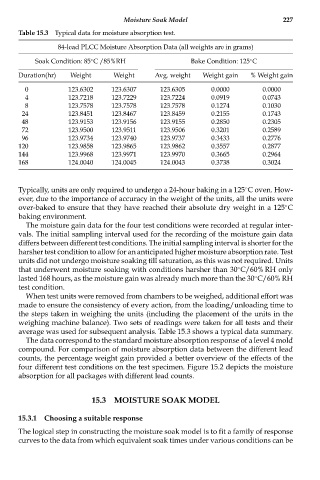

Table 15.3 Typical data for moisture absorption test.

84-lead PLCC Moisture Absorption Data (all weights are in grams)

Soak Condition: 85 C /85%RH Bake Condition: 125 C

◦

◦

Duration(hr) Weight Weight Avg. weight Weight gain % Weight gain

0 123.6302 123.6307 123.6305 0.0000 0.0000

4 123.7218 123.7229 123.7224 0.0919 0.0743

8 123.7578 123.7578 123.7578 0.1274 0.1030

24 123.8451 123.8467 123.8459 0.2155 0.1743

48 123.9153 123.9156 123.9155 0.2850 0.2305

72 123.9500 123.9511 123.9506 0.3201 0.2589

96 123.9734 123.9740 123.9737 0.3433 0.2776

120 123.9858 123.9865 123.9862 0.3557 0.2877

144 123.9968 123.9971 123.9970 0.3665 0.2964

168 124.0040 124.0045 124.0043 0.3738 0.3024

Typically, units are only required to undergo a 24-hour baking in a 125 C oven. How-

◦

ever, due to the importance of accuracy in the weight of the units, all the units were

over-baked to ensure that they have reached their absolute dry weight in a 125 C

◦

baking environment.

The moisture gain data for the four test conditions were recorded at regular inter-

vals. The initial sampling interval used for the recording of the moisture gain data

differs between different test conditions. The initial sampling interval is shorter for the

harsher test condition to allow for an anticipated higher moisture absorption rate. Test

units did not undergo moisture soaking till saturation, as this was not required. Units

◦

that underwent moisture soaking with conditions harsher than 30 C/60% RH only

lasted 168 hours, as the moisture gain was already much more than the 30 C/60% RH

◦

test condition.

When test units were removed from chambers to be weighed, additional effort was

made to ensure the consistency of every action, from the loading/unloading time to

the steps taken in weighing the units (including the placement of the units in the

weighing machine balance). Two sets of readings were taken for all tests and their

average was used for subsequent analysis. Table 15.3 shows a typical data summary.

The data correspond to the standard moisture absorption response of a level 4 mold

compound. For comparison of moisture absorption data between the different lead

counts, the percentage weight gain provided a better overview of the effects of the

four different test conditions on the test specimen. Figure 15.2 depicts the moisture

absorption for all packages with different lead counts.

15.3 MOISTURE SOAK MODEL

15.3.1 Choosing a suitable response

The logical step in constructing the moisture soak model is to fit a family of response

curves to the data from which equivalent soak times under various conditions can be