Page 2159 - Flipbook_SolidDesignSoutheast2020

P. 2159

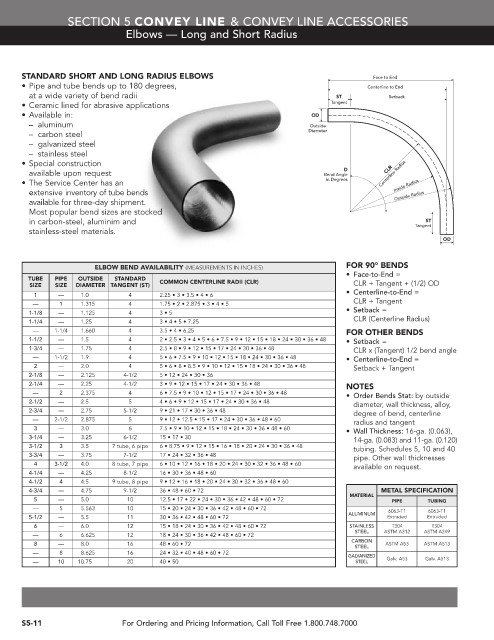

SECTION 5 CONVEY LINE & CONVEY LINE ACCESSORIES

Elbows — Long and Short Radius

STANDARD SHORT AND LONG RADIUS ELBOWS Face to End

• Pipe and tube bends up to 180 degrees, Centerline to End

at a wide variety of bend radii ST Setback

• Ceramic lined for abrasive applications Tangent

• Available in: OD

– aluminum Outside

Diameter

– carbon steel

– galvanized steel

– stainless steel

• Special construction

D CLR

available upon request Bend Angle Centerline Radius

• The Service Center has an in Degrees Inside Radius

extensive inventory of tube bends Outside Radius

available for three-day shipment.

Most popular bend sizes are stocked

in carbon-steel, aluminim and ST

Tangent

stainless-steel materials.

OD

FOR 90° BENDS

ELBOW BEND AVAILABILITY (MEASUREMENTS IN INCHES)

• Face-to-End =

TUBE PIPE OUTSIDE STANDARD COMMON CENTERLINE RADII (CLR)

SIZE SIZE DIAMETER TANGENT (ST) CLR + Tangent + (1/2) OD

• Centerline-to-End =

1 — 1.0 4 2.25 • 3 • 3.5 • 4 • 6

CLR + Tangent

— 1 1.315 4 1.75 • 2 • 2.875 • 3 • 4 • 5

• Setback =

1-1/8 — 1.125 4 3 • 5

CLR (Centerline Radius)

1-1/4 — 1.25 4 3 • 4 • 5 • 7.25

— 1-1/4 1.660 4 3.5 • 4 • 6.25 FOR OTHER BENDS

1-1/2 — 1.5 4 2 • 2.5 • 3 • 4 • 5 • 6 • 7.5 • 9 • 12 • 15 • 18 • 24 • 30 • 36 • 48

• Setback =

1-3/4 — 1.75 4 2.5 • 8 • 9 • 12 • 15 • 17 • 24 • 30 • 36 • 48

CLR x (Tangent) 1/2 bend angle

— 1-1/2 1.9 4 5 • 6 • 7.5 • 9 • 10 • 12 • 15 • 18 • 24 • 30 • 36 • 48

• Centerline-to-End =

2 — 2.0 4 5 • 6 • 8 • 8.5 • 9 • 10 • 12 • 15 • 18 • 24 • 30 • 36 • 48

Setback + Tangent

2-1/8 — 2.125 4-1/2 5 • 12 • 24 • 30 • 36

2-1/4 — 2.25 4-1/2 3 • 9 • 12 • 15 • 17 • 24 • 30 • 36 • 48 NOTES

— 2 2.375 4 6 • 7.5 • 9 • 10 • 12 • 15 • 17 • 24 • 30 • 36 • 48

• Order Bends Stat: by outside

2-1/2 — 2.5 5 4 • 6 • 9 • 12 • 15 • 17 • 24 • 30 • 36 • 48

diameter, wall thickness, alloy,

2-3/4 — 2.75 5-1/2 9 • 21 • 17 • 30 • 36 • 48

degree of bend, centerline

— 2-1/2 2.875 5 9 • 12 • 12.5 • 15 • 17 • 24 • 30 • 36 • 48 • 60

radius and tangent

3 — 3.0 6 7.5 • 9 • 10 • 12 • 15 • 18 • 24 • 30 • 36 • 48 • 60

• Wall Thickness: 16-ga. (0.063),

3-1/4 — 3.25 6-1/2 15 • 17 • 30

14-ga. (0.083) and 11-ga. (0.120)

3-1/2 3 3.5 7 tube, 6 pipe 6 • 8.75 • 9 • 12 • 15 • 16 • 18 • 20 • 24 • 30 • 36 • 48

tubing. Schedules 5, 10 and 40

3-3/4 — 3.75 7-1/2 17 • 24 • 32 • 36 • 48

pipe. Other wall thicknesses

4 3-1/2 4.0 8 tube, 7 pipe 6 • 10 • 12 • 16 • 18 • 20 • 24 • 30 • 32 • 36 • 48 • 60

available on request.

4-1/4 — 4.25 8-1/2 16 • 30 • 36 • 48 • 60

4-1/2 4 4.5 9 tube, 8 pipe 9 • 12 • 16 • 18 • 20 • 24 • 30 • 32 • 36 • 48 • 60

4-3/4 — 4.75 9-1/2 36 • 48 • 60 • 72 METAL SPECIFICATION

MATERIAL

5 — 5.0 10 12.5 • 17 • 22 • 24 • 30 • 36 • 42 • 48 • 60 • 72 PIPE TUBING

— 5 5.563 10 15 • 20 • 24 • 30 • 36 • 42 • 48 • 60 • 72

ALUMINUM 6063-T1 6063-T1

5-1/2 — 5.5 11 30 • 36 • 42 • 48 • 60 • 72 Extruded Extruded

6 — 6.0 12 15 • 18 • 24 • 30 • 36 • 42 • 48 • 60 • 72 STAINLESS T304 T304

STEEL ASTM A312 ASTM A249

— 6 6.625 12 18 • 24 • 30 • 36 • 42 • 48 • 60 • 72

CARBON

8 — 8.0 16 48 • 60 • 72 ASTM A53 ASTM A513

STEEL

— 8 8.625 16 24 • 32 • 40 • 48 • 60 • 72

GALVANIZED

— 10 10.75 20 40 • 50 STEEL Galv. A53 Galv. A513

S5-11 For Ordering and Pricing Information, Call Toll Free 1.800.748.7000