Page 2386 - Flipbook_SolidDesignSoutheast2020

P. 2386

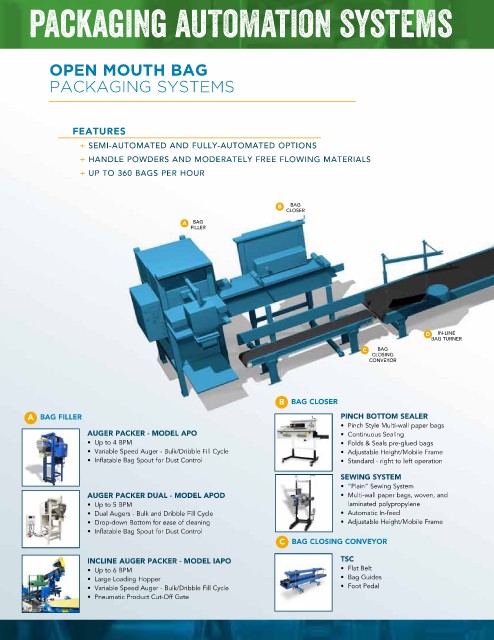

packaging automation systems

OPEN MOUTH BAG

PACKAGING SYSTEMS

FEATURES

+ SEMI-AUTOMATED AND FULLY-AUTOMATED OPTIONS

+ HANDLE POWDERS AND MODERATELY FREE FLOWING MATERIALS

+ UP TO 360 BAGS PER HOUR

B BAG

CLOSER

A BAG

FILLER

D IN-LINE

BAG TURNER

C BAG

CLOSING

CONVEYOR

B BAG CLOSER

A BAG FILLER PINCH BOTTOM SEALER

• Pinch Style Multi-wall paper bags

AUGER PACKER - MODEL APO • Continuous Sealing

• Up to 4 BPM • Folds & Seals pre-glued bags

• Variable Speed Auger - Bulk/Dribble Fill Cycle • Adjustable Height/Mobile Frame

• Inflatable Bag Spout for Dust Control • Standard - right to left operation

SEWING SYSTEM

• “Plain” Sewing System

AUGER PACKER DUAL - MODEL APOD • Multi-wall paper bags, woven, and

• Up to 5 BPM laminated polypropylene

• Dual Augers - Bulk and Dribble Fill Cycle • Automatic In-feed

• Drop-down Bottom for ease of cleaning • Adjustable Height/Mobile Frame

• Inflatable Bag Spout for Dust Control

C BAG CLOSING CONVEYOR

INCLINE AUGER PACKER - MODEL IAPO TSC

• Up to 6 BPM • Flat Belt

• Large Loading Hopper • Bag Guides

• Variable Speed Auger - Bulk/Dribble Fill Cycle • Foot Pedal

• Pneumatic Product Cut-Off Gate