Page 2388 - Flipbook_SolidDesignSoutheast2020

P. 2388

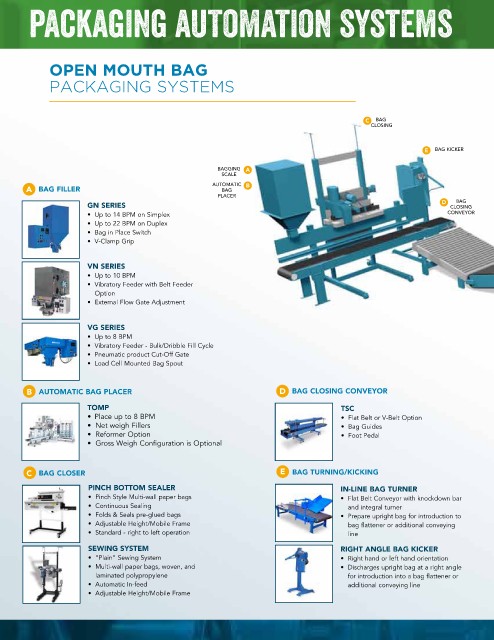

packaging automation systems

OPEN MOUTH BAG

PACKAGING SYSTEMS

C BAG

CLOSING

E BAG KICKER

BAGGING A

SCALE

AUTOMATIC B

A BAG FILLER BAG

PLACER

D BAG

GN SERIES CLOSING

• Up to 14 BPM on Simplex CONVEYOR

• Up to 22 BPM on Duplex

• Bag in Place Switch

• V-Clamp Grip

VN SERIES

• Up to 10 BPM

• Vibratory Feeder with Belt Feeder

Option

• External Flow Gate Adjustment

VG SERIES

• Up to 8 BPM

• Vibratory Feeder - Bulk/Dribble Fill Cycle

• Pneumatic product Cut-Off Gate

• Load Cell Mounted Bag Spout

B AUTOMATIC BAG PLACER D BAG CLOSING CONVEYOR

TOMP TSC

• Place up to 8 BPM • Flat Belt or V-Belt Option

• Net weigh Fillers • Bag Guides

• Reformer Option • Foot Pedal

• Gross Weigh Configuration is Optional

C BAG CLOSER E BAG TURNING/KICKING

PINCH BOTTOM SEALER IN-LINE BAG TURNER

• Pinch Style Multi-wall paper bags • Flat Belt Conveyor with knockdown bar

• Continuous Sealing and integral turner

• Folds & Seals pre-glued bags • Prepare upright bag for introduction to

• Adjustable Height/Mobile Frame bag flattener or additional conveying

• Standard - right to left operation line

SEWING SYSTEM RIGHT ANGLE BAG KICKER

• “Plain” Sewing System • Right hand or left hand orientation

• Multi-wall paper bags, woven, and • Discharges upright bag at a right angle

laminated polypropylene for introduction into a bag flattener or

• Automatic In-feed additional conveying line

• Adjustable Height/Mobile Frame