Page 2790 - Flipbook_SolidDesignSoutheast2020

P. 2790

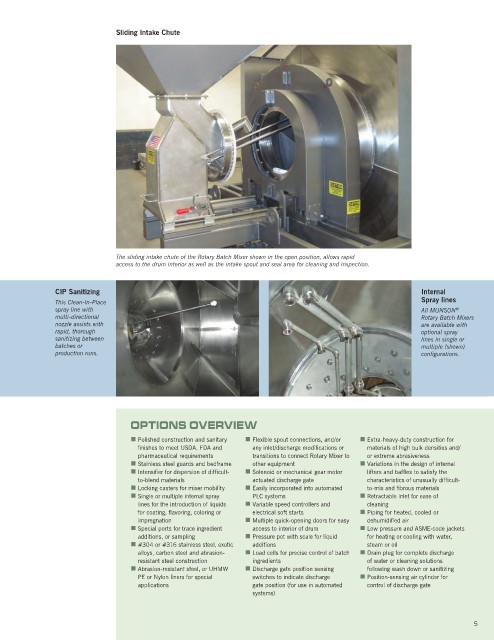

Sliding Intake Chute

The sliding intake chute of the Rotary Batch Mixer shown in the open position, allows rapid

access to the drum interior as well as the intake spout and seal area for cleaning and inspection.

CIP Sanitizing Internal

This Clean-In-Place Spray lines

spray line with All MUNSON

®

multi-directional Rotary Batch Mixers

nozzle assists with are available with

rapid, thorough optional spray

sanitizing between lines in single or

batches or multiple (shown)

production runs. configurations.

OPTIONS OVERVIEW

n Polished construction and sanitary n Flexible spout connections, and/or n Extra-heavy-duty construction for

finishes to meet USDA, FDA and any inlet/discharge modifications or materials of high bulk densities and/

pharmaceutical requirements transitions to connect Rotary Mixer to or extreme abrasiveness

n Stainless steel guards and bedframe other equipment n Variations in the design of internal

I

n ntensifier for dispersion of difficult- n Solenoid or mechanical gear motor lifters and baffles to satisfy the

to-blend materials actuated discharge gate characteristics of unusually difficult-

n Locking casters for mixer mobility n Easily incorporated into automated to-mix and fibrous materials

n Single or multiple internal spray PLC systems n Retractable inlet for ease of

lines for the introduction of liquids n Variable speed controllers and cleaning

for coating, flavoring, coloring or electrical soft starts n Piping for heated, cooled or

impregnation n Multiple quick-opening doors for easy dehumidified air

n Special ports for trace ingredient access to interior of drum n Low pressure and ASME-code jackets

additions, or sampling n Pressure pot with scale for liquid for heating or cooling with water,

n #304 or #316 stainless steel, exotic additions steam or oil

alloys, carbon steel and abrasion- n Load cells for precise control of batch n Drain plug for complete discharge

resistant steel construction ingredients of water or cleaning solutions

n Abrasion-resistant steel, or UHMW n Discharge gate position sensing following wash down or sanitizing

PE or Nylon liners for special switches to indicate discharge n Position-sensing air cylinder for

applications gate position (for use in automated control of discharge gate

systems)

5