Page 2793 - Flipbook_SolidDesignSoutheast2020

P. 2793

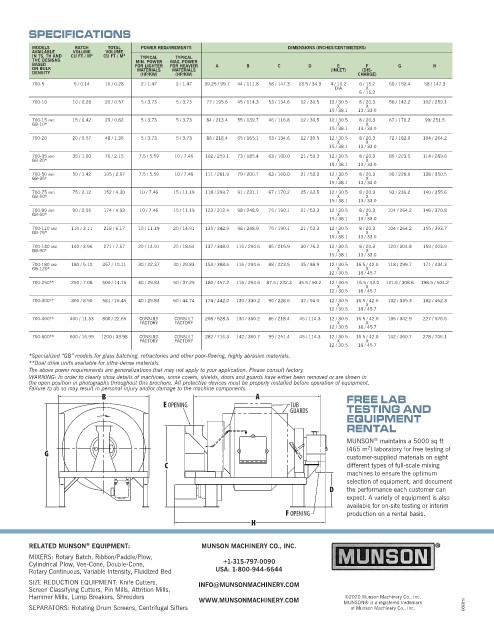

SPECIFICATIONS

MODELS BATCH TOTAL POWER REQUIREMENTS DIMENSIONS (INCHES/CENTIMETERS)

AVAILABLE VOLUME VOLUME

IN TS, TH AND CU FT / M 3 CU FT / M 3 TYPICAL TYPICAL

THC DESIGNS MIN. POWER MAX. POWER

BASED FOR LIGHTER FOR HEAVIER A B C D E F G H

ON BULK MATERIALS MATERIALS (INLET) (DIS-

DENSITY (HP/KW) (HP/KW) CHARGE)

700-5 5 / 0.14 10 / 0.28 2 / 1.47 2 / 1.47 39.25 / 99.7 44 / 111.8 58 / 147.3 13.5 / 34.3 4 / 10.2 6 / 15.2 60 / 152.4 58 / 147.3

DIA X

6 / 15.2

700-10 10 / 0.28 20 / 0.57 5 / 3.73 5 / 3.73 77 / 195.6 45 / 114.3 53 / 134.6 12 / 30.5 12 / 30.5 8 / 20.3 56 / 142.2 102 / 259.1

X X

15 / 38.1 13 / 33.0

700-15 AnD 15 / 0.42 29 / 0.82 5 / 3.73 5 / 3.73 84 / 213.4 55 / 139.7 46 / 116.8 12 / 30.5 12 / 30.5 8 / 20.3 67 / 170.2 99/ 251.5

GB-10* X X

15 / 38.1 13 / 33.0

700-20 20 / 0.57 48 / 1.36 5 / 3.73 5 / 3.73 86 / 218.4 65 / 165.1 53 / 134.6 12 / 30.5 12 / 30.5 8 / 20.3 72 / 182.9 104 / 264.2

X X

15 / 38.1 13 / 33.0

700-35 AnD 35 / 1.00 76 / 2.15 7.5 / 5.59 10 / 7.46 102 / 259.1 73 / 185.4 63 / 160.0 21 / 53.3 12 / 30.5 8 / 20.3 80 / 223.5 114 / 289.6

GB-20* X X

15 / 38.1 13 / 33.0

700-50 AnD 50 / 1.42 105 / 2.97 7.5 / 5.59 10 / 7.46 111 / 281.9 79 / 200.7 63 / 160.0 21 / 53.3 12 / 30.5 8 / 20.3 90 / 228.6 138 / 350.5

GB-35* X X

15 / 38.1 13 / 33.0

700-75 AnD 75 / 2.12 152 / 4.30 10 / 7.46 15 / 11.19 118 / 299.7 91 / 231.1 67 / 170.2 25 / 63.5 12 / 30.5 8 / 20.3 93 / 236.2 140 / 355.6

GB-50* X X

15 / 38.1 13 / 33.0

700-90 AnD 90 / 2.55 174 / 4.93 10 / 7.46 15 / 11.19 123 / 312.4 98 / 248.9 75 / 190.1 21 / 53.3 12 / 30.5 8 / 20.3 104 / 264.2 146 / 370.8

GB-60* X X

15 / 38.1 13 / 33.0

700-110 AnD 110 / 3.11 218 / 6.17 15 / 11.19 20 / 14.91 135 / 342.9 98 / 248.9 75 / 190.1 21 / 53.3 12 / 30.5 8 / 20.3 104 / 264.2 155 / 393.7

GB-75* X X

15 / 38.1 13 / 33.0

700-140 AnD 140 / 3.96 271 / 7.67 20 / 14.91 25 / 18.64 137 / 348.0 116 / 294.6 85 / 215.9 30 / 76.2 12 / 30.5 8 / 20.3 120 / 304.8 159 / 403.9

GB-90* X X

15 / 38.1 13 / 33.0

700-180 AnD 180 / 5.10 357 / 10.11 30 / 22.37 40 / 29.83 153 / 388.6 116 / 294.6 88 / 223.5 35 / 88.9 12 / 30.5 16.5 / 42.0 118 / 299.7 171 / 434.3

GB-120* X X

12 / 30.5 18 / 45.7

700-250** 250 / 7.08 500 / 14.16 40 / 29.83 50 / 37.29 180 / 457.2 116 / 294.6 87.5 / 222.3 35.5 / 90.2 12 / 30.5 16.5 / 42.0 121.5 / 308.6 198.5 / 504.2

X X

12 / 30.5 18 / 45.7

700-300** 300 / 8.50 581 / 16.45 40 / 29.83 60 / 44.74 174 / 442.0 130 / 330.2 90 / 228.6 37 / 94.0 12 / 30.5 16.5 / 42.0 132 / 335.3 182 / 462.3

X X

12 / 30.5 18 / 45.7

700-400** 400 / 11.33 800 / 22.65 COnSULT COnSULT 208 / 528.3 130 / 330.2 86 / 218.4 45 / 114.3 12 / 30.5 16.5 / 42.0 135 / 342.9 227 / 576.6

FACTORY FACTORY X X

12 / 30.5 18 / 45.7

700-600** 600 / 16.99 1200 / 33.98 COnSULT COnSULT 282 / 716.3 142 / 360.7 99 / 251.4 45 / 114.3 12 / 30.5 16.5 / 42.0 142 / 360.7 278 / 706.1

FACTORY FACTORY X X

12 / 30.5 18 / 45.7

*Specialized “GB” models for glass batching, refractories and other poor-flowing, highly abrasive materials.

**Dual drive units available for ultra-dense materials.

The above power requirements are generalizations that may not apply to your application. Please consult factory.

WARNING: In order to clearly show details of machines, some covers, shields, doors and guards have either been removed or are shown in

the open position in photographs throughout this brochure. All protective devices must be properly installed before operation of equipment.

Failure to do so may result in personal injury and/or damage to the machine components.

B A FREE LAB

E OPENING TUB TESTING AND

GUARDS

EQUIPMENT

RENTAL

®

MUNSON maintains a 5000 sq ft

2

(465 m ) laboratory for free testing of

G customer-supplied materials on eight

C different types of full-scale mixing

machines to ensure the optimum

selection of equipment, and document

D the performance each customer can

expect. A variety of equipment is also

available for on-site testing or interim

F OPENING production on a rental basis.

H

®

RELATED MUNSON EQUIPMENT: MUNSON MACHINERY CO., INC.

MIXERS: Rotary Batch, Ribbon/Paddle/Plow,

Cylindrical Plow, Vee-Cone, Double-Cone, +1-315-797-0090

Rotary Continuous, Variable Intensity, Fluidized Bed USA: 1-800-944-6644

SIZE REDUCTION EQUIPMENT: Knife Cutters, INFO@MUNSONMACHINERY.COM

Screen Classifying Cutters, Pin Mills, Attrition Mills,

Hammer Mills, Lump Breakers, Shredders ©2020 Munson Machinery Co., Inc.

WWW.MUNSONMACHINERY.COM MUNSON® is a registered trademark

SEPARATORS: Rotating Drum Screens, Centrifugal Sifters of Munson Machinery Co., Inc. II-0393