Page 2797 - Flipbook_SolidDesignSoutheast2020

P. 2797

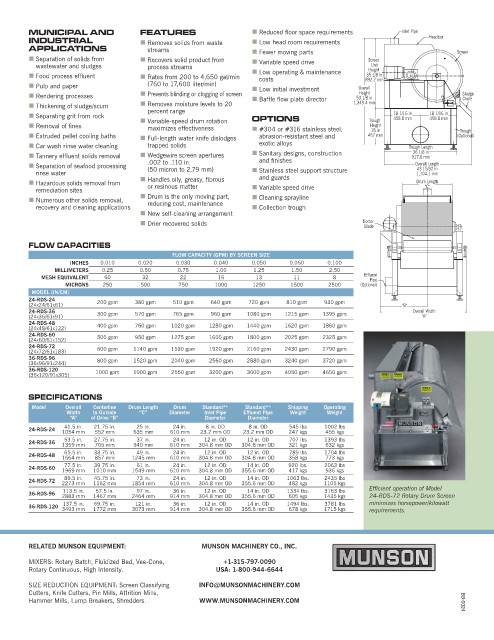

MUNICIPAL AND FEATURES n Reduced floor space requirements Inlet Pipe

INDUSTRIAL n Removes solids from waste n Low head room requirements Headbox

APPLICATIONS streams n Fewer moving parts Screen

n Separation of solids from n Recovers solid product from n Variable speed drive Screen

wastewater and sludges process streams Height

Unit

35 1/8 in

n Food process effluent n Rates from 200 to 4,650 gal/min n Low operating & maintenance 892.2 mm

costs

n Pulp and paper (760 to 17,600 liter/min) n Low initial investment Overall

Height

n Rendering processes n Prevents blinding or clogging of screen n Baffle flow plate director 53 1/8 in Sludge

Chute

n Thickening of sludge/scum n Removes moisture levels to 20 1,349.4 mm

percent range

n Separating grit from rock n Variable-speed drum rotation OPTIONS Trough 18 1/16 in 18 1/16 in

458.8 mm

458.8 mm

n Removal of fines maximizes effectiveness n #304 or #316 stainless steel, Height Trough

18 in

n Extruded pellet cooling baths n Full-length water knife dislodges abrasion-resistant steel and 457 mm (Optional)

n Car wash rinse water cleaning trapped solids exotic alloys Trough Length

36 1/8 in

n Tannery effluent solids removal n Wedgewire screen apertures n Sanitary designs, construction 917.6 mm

and finishes

n Separation of seafood processing .002 to .110 in. Overall Length

(50 micron to 2.79 mm)

43 15/32 in

rinse water n Stainless steel support structure 1,104.1 mm

and guards

n Hazardous solids removal from n Handles oily, greasy, fibrous Drum Length

or resinous matter

"C"

remediation sites n Variable speed drive

n Numerous other solids removal, n Drum is the only moving part, n Cleaning sprayline

reducing cost, maintenance

recovery and cleaning applications n Collection trough

n New self-cleaning arrangement

n Drier recovered solids Doctor

Blade

FLOW CAPACITIES

FLOW CAPACITY (GPM) BY SCREEN SIZE

INCHES 0.010 0.020 0.030 0.040 0.050 0.060 0.100

MILLIMETERS 0.25 0.50 0.75 1.00 1.25 1.50 2.50

MESH EQUIVALENT 60 32 22 16 13 11 8 Effluent

Pipe

MICRONS 250 500 750 1000 1250 1500 2500 (Optional)

MODEL (IN/CM)

24-RDS-24 200 gpm 380 gpm 510 gpm 640 gpm 720 gpm 810 gpm 930 gpm

(24x24/61x61) "B"

24-RDS-36 300 gpm 570 gpm 765 gpm 960 gpm 1080 gpm 1215 gpm 1395 gpm Overall Width

(24x36/61x91) "A"

24-RDS-48 400 gpm 760 gpm 1020 gpm 1280 gpm 1440 gpm 1620 gpm 1860 gpm

(24x48/61x122)

24-RDS-60 500 gpm 950 gpm 1275 gpm 1600 gpm 1800 gpm 2025 gpm 2325 gpm

(24x60/61x152)

24-RDS-72 600 gpm 1140 gpm 1530 gpm 1920 gpm 2160 gpm 2430 gpm 2790 gpm

(24x72/61x183)

36-RDS-96 800 gpm 1520 gpm 2040 gpm 2560 gpm 2880 gpm 3240 gpm 3720 gpm

(36x96/91x244)

36-RDS-120 1000 gpm 1900 gpm 2550 gpm 3200 gpm 3600 gpm 4050 gpm 4650 gpm

(36x120/91x305)

SPECIFICATIONS

Model Overall Centerline Drum Length Drum Standard** Standard** Shipping Operating

Width to Outside “C” Diameter Inlet Pipe Effluent Pipe Weight Weight

“A” of Drive “B” Diameter Diameter

41.5 in.

8 in. OD

8 in. OD

24 in.

25 in.

24-RDS-24 1054 mm 21.75 in. 635 mm 610 mm 23.2 mm OD 23.2 mm OD 545 lbs 1002 lbs

552 mm

455 kgs

247 kgs

37 in.

53.5 in.

24 in.

12 in. OD

12 in. OD

24-RDS-36 1359 mm 27.75 in. 940 mm 610 mm 304.8 mm OD 304.8 mm OD 707 lbs 1393 lbs

705 mm

321 kgs

632 kgs

12 in. OD

12 in. OD

65.5 in.

49 in.

24 in.

24-RDS-48 1664 mm 33.75 in. 1245 mm 610 mm 304.8 mm OD 304.8 mm OD 789 lbs 1704 lbs

358 kgs

857 mm

773 kgs

77.5 in. 39.75 in. 61 in. 24 in. 12 in. OD 14 in. OD 920 lbs. 2063 lbs

24-RDS-60 1969 mm 1010 mm 1549 mm 610 mm 304.8 mm OD 355.6 mm OD 417 kgs 936 kgs

89.5 in. 45.75 in. 73 in. 24 in. 12 in. OD 14 in. OD 1063 lbs. 2435 lbs

24-RDS-72 2273 mm 1162 mm 1854 mm 610 mm 304.8 mm OD 355.6 mm OD 482 kgs 1105 kgs

3163 lbs

57.5 in.

12 in. OD

14 in. OD

97 in.

113.5 in.

36 in.

36-RDS-96 2883 mm 1467 mm 2464 mm 914 mm 304.8 mm OD 355.6 mm OD 1334 lbs. 1435 kgs Efficient operation of Model

24-RDS-72 Rotary Drum Screen

605 kgs

121 in.

36 in.

14 in. OD

137.5 in.

69.75 in.

12 in. OD

3781 lbs

36-RDS-120 3493 mm 1772 mm 3073 mm 914 mm 304.8 mm OD 355.6 mm OD 1494 lbs. 1715 kgs minimizes horsepower/kilowatt

678 kgs

requirements.

RELATED MUNSON EQUIPMENT: MUNSON MACHINERY CO., INC.

MIXERS: Rotary Batch, Fluidized Bed, Vee-Cone, +1-315-797-0090

Rotary Continuous, High Intensity. USA: 1-800-944-6644

SIZE REDUCTION EQUIPMENT: Screen Classifying INFO@MUNSONMACHINERY.COM

Cutters, Knife Cutters, Pin Mills, Attrition Mills,

Hammer Mills, Lump Breakers, Shredders. WWW.MUNSONMACHINERY.COM BB-0324