Page 2794 - Flipbook_SolidDesignSoutheast2020

P. 2794

ROTARY CONTINUOUS MIXERS

Slash capital and operational costs when blending long runs of dry bulk

solids with or without liquid additions, quickly, uniformly and gently

n Low cost mixing of long n Handles abrasive and

product runs corrosive products, and Proprietary mixing

flights produce a gentle

n Low labor costs compared materials with high yet efficient back-flow

to batch mixers bulk densities mixing action free of

n Gentle action prevents n Automatic material evacu- dead spots or internal

restrictions. Optional

ation at the end of product

material degradation runs using an optional piping (shown) through

n Accurate blend ratios reversing discharge weir discharge end feeds

to 99.9% n Small footprint per amount liquids through nozzles

onto continuously

n Rapid mixing: 1 to 2 minutes of material processed moving material for

residence time typical n Industrial and sanitary rapid, thorough coating.

n Lowest energy use per designs, construction and

amount of material blended finishes A money-saving machine for required to feed ingredients into the

n Stationary inlet and n Long life with minimal mixing of bulk materials in large stationary material inlet. Material

stationary outlet allow maintenance volumes, the Munson Rotary depth is generally set at 25 to 30%

for hard piping Continuous Mixer blends primary by means of a “weir” (dam) at the

bulk ingredients, minor ingredients discharge end of the drum, with

down to 0.1 percent, and/or liquid residence time and the amount of

The Munson Rotary Continuous Mixer cuts additions and coatings—uniformly, blended material overflowing the

labor and operational costs dramatically gently, rapidly and dust-free. weir determined by the residence

volume of the rotating cylinder and

when mixing dry bulk solids, with or In an automated system, the the rate of material inflow.

without liquid additions, in-line over long Munson Rotary Continuous Mixer Residence times generally range

typically requires only a portion of

product runs. Delivers uniform blends— a single operator’s time to monitor from one to two minutes. Longer

typically in one to two minutes residence the machine, unlike batch mixers residence times may be required

for critical blends containing minor

that can require multiple operators

time—gently and with low energy use. to stage materials, feed the additives, or for materials that

machine and unload it. require increased dwell time for

absorption or other conditioning.

The first dry process mixer

purpose-built for continuous For liquid additions and coatings,

operation, it features a stationary an optional spray line mounted

inlet, a stationary outlet, and a above the material bed, sprays

rotating drum with smooth interior liquid onto the cascading material,

surfaces and proprietary mixing assuring that every particle is

flights that mix dynamically with exposed to the spray pattern,

every degree of drum rotation. yielding uniform coatings.

Only a small electric motor is

required to rotate the drum at a

constant 8 to 10 RPM, saving on

initial cost and power consumption.

The low speed yet highly-efficient

tumbling action—with no impeller

or agitator—cuts residence time

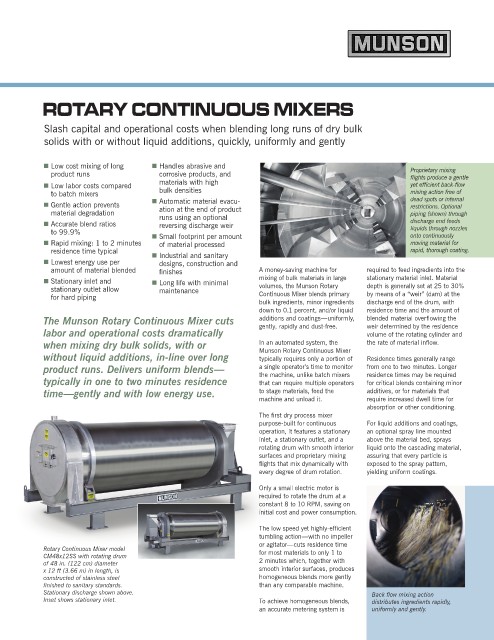

Rotary Continuous Mixer model for most materials to only 1 to

CM48x12SS with rotating drum

of 48 in. (122 cm) diameter 2 minutes which, together with

x 12 ft (3.66 m) in length, is smooth interior surfaces, produces

constructed of stainless steel homogeneous blends more gently

finished to sanitary standards. than any comparable machine.

Stationary discharge shown above. Back flow mixing action

Inset shows stationary inlet. To achieve homogeneous blends, distributes ingredients rapidly,

an accurate metering system is uniformly and gently.