Page 2798 - Flipbook_SolidDesignSoutheast2020

P. 2798

ROTARY KNIFE CUTTER

Cut corn, spices, roots, and other foods and grains into controlled sizes

gently, sharply and accurately, with little or no fines or dust

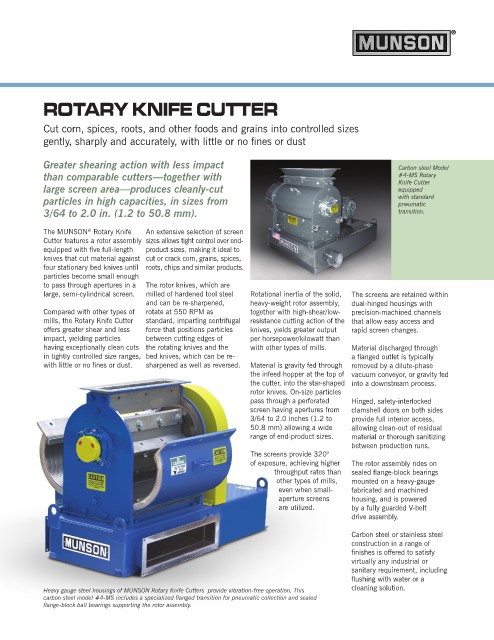

Greater shearing action with less impact Carbon steel Model

than comparable cutters––together with #4-MS Rotary

large screen area––produces cleanly-cut Knife Cutter

equipped

particles in high capacities, in sizes from with standard

pneumatic

3/64 to 2.0 in. (1.2 to 50.8 mm). transition.

The MUNSON Rotary Knife An extensive selection of screen

®

Cutter features a rotor assembly sizes allows tight control over end-

equipped with five full-length product sizes, making it ideal to

knives that cut material against cut or crack corn, grains, spices,

four stationary bed knives until roots, chips and similar products.

particles become small enough

to pass through apertures in a The rotor knives, which are

large, semi-cylindrical screen. milled of hardened tool steel Rotational inertia of the solid, The screens are retained within

and can be re-sharpened, heavy-weight rotor assembly, dual-hinged housings with

Compared with other types of rotate at 550 RPM as together with high-shear/low- precision-machined channels

mills, the Rotary Knife Cutter standard, imparting centrifugal resistance cutting action of the that allow easy access and

offers greater shear and less force that positions particles knives, yields greater output rapid screen changes.

impact, yielding particles between cutting edges of per horsepower/kilowatt than

having exceptionally clean cuts the rotating knives and the with other types of mills. Material discharged through

in tightly controlled size ranges, bed knives, which can be re- a flanged outlet is typically

with little or no fines or dust. sharpened as well as reversed. Material is gravity fed through removed by a dilute-phase

the infeed hopper at the top of vacuum conveyor, or gravity fed

the cutter, into the star-shaped into a downstream process.

rotor knives. On-size particles

pass through a perforated Hinged, safety-interlocked

screen having apertures from clamshell doors on both sides

3/64 to 2.0 inches (1.2 to provide full interior access,

50.8 mm) allowing a wide allowing clean-out of residual

range of end-product sizes. material or thorough sanitizing

between production runs.

The screens provide 320°

of exposure, achieving higher The rotor assembly rides on

throughput rates than sealed flange-block bearings

other types of mills, mounted on a heavy-gauge

even when small- fabricated and machined

aperture screens housing, and is powered

are utilized. by a fully guarded V-belt

drive assembly.

Carbon steel or stainless steel

construction in a range of

finishes is offered to satisfy

virtually any industrial or

sanitary requirement, including

flushing with water or a

Heavy gauge steel housings of MUNSON Rotary Knife Cutters provide vibration-free operation. This cleaning solution.

carbon steel model #4-MS includes a specialized flanged transition for pneumatic collection and sealed

flange-block ball bearings supporting the rotor assembly.