Page 12 - MILLING-TOOLS-yg1

P. 12

CASE STUDY CASE STUDY

i-Xmill End mills Reference page : p.55 ~ p.79 i-SMART Modular Type End mills Reference page : p.81 ~ p.99

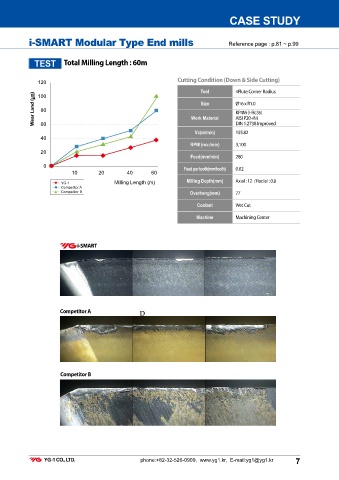

with Diamond Coating TEST Total Milling Length : 60m

120 Cutting Condition (Down & Side Cutting)

60 Cutting Condition Tool 4Flute Corner Radius

Improved Tool Life Tool i-Xmill Corner Radius 100

50 (XMR110D17010) 80 Size Ø16 x R1.0

Size Ø17 x R1.0 Wear Land (㎛) Work Material KP4M (HRc35)

AISI P20+Ni

40 Work Material Graphite 60 Vc(m/min) DIN 1.2738 Improved

Tool Life (hours) 30 RPM (rev./min) 320 40 RPM (rev./min) 3,100

155.82

Vc(m/min)

6,000

20

Feed(mm/min)

280

Feed(mm/min)

2,800

20

Feed per tooth(mm/tooth) 0.23 0 10 20 40 60 Feed per tooth(mm/tooth) 0.02

10 Milling Depth(mm) Axial : 0.2 YG-1 Milling Length (m) Milling Depth(mm) Axial : 12 / Radial : 0.8

Competitor A

Competitor B Overhang(mm) 77

Coolant Air

0 Coolant Wet Cut

Diamond Coating Conventional Coating

(XMR110D17010) (PVD) Machine Machining Center

i-SMART

Coating properties

This coating generation features a good crystalline structure.

It protects tools perfectly against abrasive wear and is

unsurpassed in graphite cutting.

Diamond Layer

Feature Competitor A

1. High Abrasive wear resistance. D

2. Good Coefficient of friction.(against Al)

3. High Precision. Base material

Advantages

Diamond coated i-Xmill possible to cut graphite workpieces

with substantially greater speeds and in significantly better Crystalline

quality. Competitor B

structure

Applications

1. Precision-structured graphite electrodes.

2. Micro-Electromechanical Systems. (MEMS)

3. Printed Circuit Boards. (PCBs)

4. Ceramics (greens, sintered) Dental, machinery.

6 phone:+82-32-526-0909, www.yg1.kr, E-mail:yg1@yg1.kr phone:+82-32-526-0909, www.yg1.kr, E-mail:yg1@yg1.kr 7