Page 14 - MILLING-TOOLS-yg1

P. 14

CASE STUDY CASE STUDY

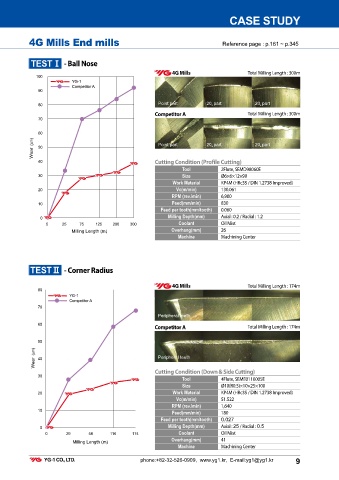

X5070 End mills Reference page : p.101 ~ p.159 4G Mills End mills Reference page : p.161 ~ p.345

Carbide 6 Flute 45° Helix End mill for Hardened Steel TEST I - Ball Nose

4G Mills Total Milling Length : 300m

45 Cutting Condition (Down & Side Cutting) 100

YG-1

Competitor A Tool 6Flute 45° Helix

40

Size Ø16×Ø16×40×110 100 90

35

JIS : SKD61(HRc50) Point part 20。part 20。part

30 Work Material DIN : X40CrMoV5-1(1.2344) 90 80

AISI : H13 Competitor A Total Milling Length : 300m

25 Vc(m/min) 96.5 80 70

20 RPM (rev./min) 1,920 70 60

15 Feed(mm/min) 912 Point part 20。part 20。part

Milling Depth(mm) Axial : 24 / Radial : 0.96 60 50

10 Wear

Coolant Dry Cut

5 50 40 Cutting Condition (Profile Cutting)

Overhang(mm) 52 Wear Tool 2Flute, SEMD98060E

0 Machine Machining Center 40

0 50 100 30 Size Ø6×6×12×90

Work Material KP4M (HRc35 / DIN 1.2738 Improved)

30 20 Vc(m/min) 130.061

RPM (rev./min) 6,900

X5070 20 Feed(mm/min) 830

(Total Milling Length : 100m) 10 Feed per tooth(mm/tooth) 0.060

10 0 Milling Depth(mm) Axial : 0.2 / Radial : 1.2

5 25 75 125 200 300 Coolant Oil Mist

0 Milling Length (m) Overhang(mm) 26

Competitor A 5 25 75 125 200 300 Machine

(Total Milling Length : 100m) Milling Length (m) Machining Center

Carbide 4 Flute Center match Ball Nose End mill for Hardened Steel TEST II - Corner Radius

350 Cutting Condition (Side Cutting) 80 4G Mills Total Milling Length : 174m

YG-1 Tool 4Flute Ball Nose

Competitor A

300 Size Ø10×Ø10×18×100 100 70

JIS : SKD11(HRc60)

250 Work Material DIN : X155CrVMo12-1(1.2379) 90 Peripheral teeth

AISI : D2 60 Competitor A Total Milling Length : 174m

200 Vc(m/min) 210.486 80

RPM (rev./min) 6,700 50

150

Feed(mm/min) 2,800 70

100 Milling Depth(mm) Axial : 0.2 / Radial : 0.5 60 40 Peripheral teeth

Coolant Oil Mist Wear

50 Cutting Condition (Down & Side Cutting)

Overhang(mm) 32 Wear 50 30 Tool 4Flute, SEME0110005E

0 Machine Machining Center 40 Size Ø10(R0.5)×10×25×100

0 210 360 540 20 Work Material KP4M (HRc35 / DIN 1.2738 Improved)

Vc(m/min) 51.522

30 RPM (rev./min) 1,640

10 Feed(mm/min) 180

20 Feed per tooth(mm/tooth) 0.027

X5070 Competitor A Milling Depth(mm) Axial : 25 / Radial : 0.5

(Total Milling Length : 540m) (Total Milling Length : 210m) 10 0 0 29 58 116 174 Coolant Oil Mist

Milling Length (m) Overhang(mm) 41

0 Machine Machining Center

5 25 75 125 200 300

8 phone:+82-32-526-0909, www.yg1.kr, E-mail:yg1@yg1.kr Milling Length (m) phone:+82-32-526-0909, www.yg1.kr, E-mail:yg1@yg1.kr 9