Page 42 - Bullion World Issue 1 May 2021

P. 42

Bullion World | Issue 01 | May 2021

Determination of the

Silver Content of Silver

Plated or Blanched

Silver Alloys.

For finishing purposes silverware is

often plated or blanched. In the plating

process, a pure silver coating is applied

to a silver/copper alloy. This produces an

attractive, white satin sheen. Blanching Mr. Bharat Patil

achieves the same effect by chemically Fischer

removing copper from the topmost layer

of the silver/copper alloy. The result of

both methods is a veneer of much higher Using a measuring application which “ Using specialized

silver content than the substrate, which looks for a silver coating atop a applications with the

complicates the determination of the silver/copper alloy, FISCHER X-ray

fineness, and therefore, of the value of fluorescence instruments allow for the GOLDSCOPE SD® 520

the silverware. non-destructive determination of both makes it possible to

the thickness of the silver coating as well

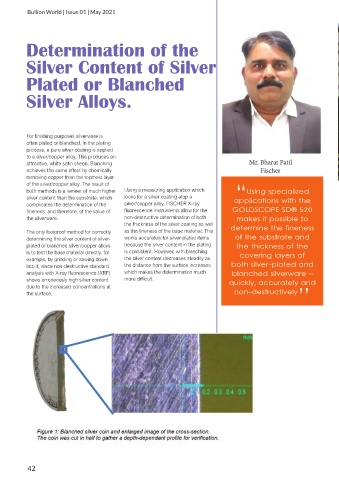

The only foolproof method for correctly as the fineness of the base material. This determine the fineness

determining the silver content of silver- works accurately for silver-plated items of the substrate and

plated or blanched silver/copper alloys because the silver content in the plating the thickness of the

is to test the base material directly, for is consistent. However, with blanching covering layers of

example, by grinding or sawing down the silver content decreases steadily as

into it, since non-destructive standard the distance from the surface increases both silver-plated and

analysis with X-ray fluorescence (XRF) which makes the determination much blanched silverware –

shows erroneously high silver content more difficult. quickly, accurately and

due to the increased concentrations at

the surface. non-destructively ’’

42